Dirk (Diskussion | Beiträge) K (→Verschaltung der Jumperblöcke) |

Dirk (Diskussion | Beiträge) K (→Beispiel 3,3V-Messung) |

||

| Zeile 9.453: | Zeile 9.453: | ||

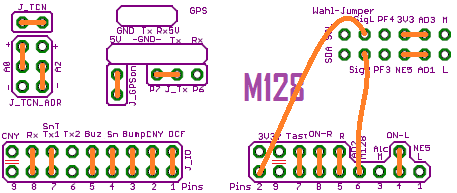

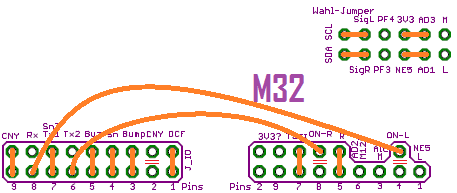

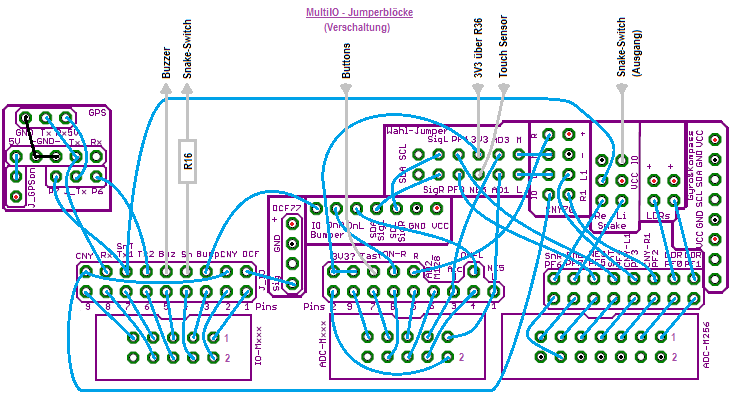

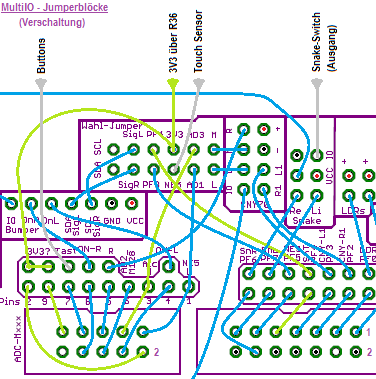

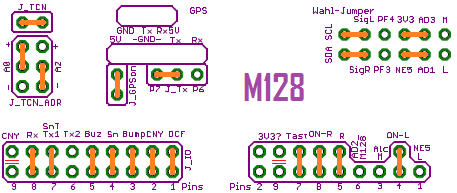

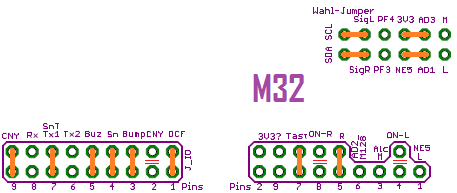

Auf der MultiIO wird ja u.a. auch vom IC MIC5219-3.3 eine 3,3V-Spannung erzeugt, die für 3,3V-Sensoren (z.B. I2C-Luftdrucksensor BMP085) genutzt werden kann. Diese Spannung kann man (zu Kontrollzwecken) auch messen. Die folgende Abbildung zeigt die (hellgrünen) Verbindungen zwischen den Jumperblöcken, die hierfür eine Rolle spielen: | Auf der MultiIO wird ja u.a. auch vom IC MIC5219-3.3 eine 3,3V-Spannung erzeugt, die für 3,3V-Sensoren (z.B. I2C-Luftdrucksensor BMP085) genutzt werden kann. Diese Spannung kann man (zu Kontrollzwecken) auch messen. Die folgende Abbildung zeigt die (hellgrünen) Verbindungen zwischen den Jumperblöcken, die hierfür eine Rolle spielen: | ||

| − | [[Bild:MultiIO- | + | [[Bild:MultiIO-Jumperbloecke_3V3.PNG|MultiIO Jumperblöcke: Verschaltung der 3,3V-Messung]] |

Verfolgt man die hellgrünen 3,3V-Mess-Verbindungen im Bild von oben nach unten, dann wird die auf der MultiIO erzeugte 3,3V-Spannung (über einen Widerstand R36) zum Pin "3V3" des Wahl-Jumper-Blocks (J_WAHL) geführt. Von dort gelangt sie direkt zu zwei Pins des Jumperblocks J_ADC (beschriftet mit "3V3?"). Setzt man auf J_ADC ganz links ("Pins 2") einen Jumper, dann endet die 3,3V-Mess-Verbindung an Pin 2 des ADC-Mxxx Steckers. Setzt man stattdessen den Jumper auf J_ADC eine Position weiter nach rechts ("Pins 9"), dann endet die Mess-Verbindung an Pin 9 des ADC-Mxxx Steckers. Für diese beiden Verbindungen ist kein Jumper auf J_WAHL erforderlich. | Verfolgt man die hellgrünen 3,3V-Mess-Verbindungen im Bild von oben nach unten, dann wird die auf der MultiIO erzeugte 3,3V-Spannung (über einen Widerstand R36) zum Pin "3V3" des Wahl-Jumper-Blocks (J_WAHL) geführt. Von dort gelangt sie direkt zu zwei Pins des Jumperblocks J_ADC (beschriftet mit "3V3?"). Setzt man auf J_ADC ganz links ("Pins 2") einen Jumper, dann endet die 3,3V-Mess-Verbindung an Pin 2 des ADC-Mxxx Steckers. Setzt man stattdessen den Jumper auf J_ADC eine Position weiter nach rechts ("Pins 9"), dann endet die Mess-Verbindung an Pin 9 des ADC-Mxxx Steckers. Für diese beiden Verbindungen ist kein Jumper auf J_WAHL erforderlich. | ||

Aktuelle Version vom 11. Januar 2016, 21:24 Uhr

Inhaltsverzeichnis

- 1 RP6 Multi IO Erweiterungsmodul

- 1.1 Hardware

- 1.2 Software

- 1.3 Technische Informationen

- 1.4 Siehe auch

- 1.5 Weblinks

- 1.6 Autoren

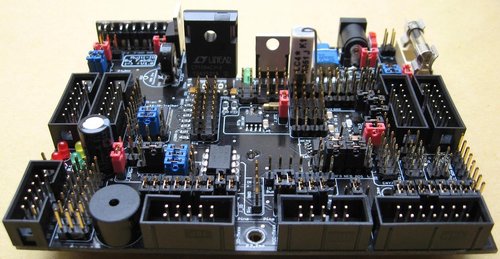

RP6 Multi IO Erweiterungsmodul

Das RP6-Multi-IO Erweiterungsmodul besteht aus fünf Platinen. Eine Hauptplatine, im üblichen RP6-Layout, enthält eine Vielzahl möglicher Sensoren und Aktoren wie Temperatursensor, Stromsensor, Berührungssensor, Servo-Ansteuerung, LEDs, Buzzer etc. An sie können die vier weiteren Platinen angesteckt werden. Diese sind eine Bumper-Platine zum Anbringen am Heck des RP6, eine Radio-Platine, eine Platine mit vier Tastern und eine mit einem Liniensensor-Array von fünf CNY70-Reflexoptokopplern.

Diese fünf Platinen können bei fabqu (oder [1]) bestellt werden. Sie sind mit Lötstopplack (schwarz) sowie beidseitig mit einem Bestückungsdruck (in weiß) versehen. Sie sind nicht aufgebaut, aber fabqu bietet an, die schwer einzulötenden SMD-ICs (und bei Bedarf auch alle anderen SMD-Bauteile) in einer einmaligen Sammelbestellung zu bestellen und einzulöten.

Umfangreiche Dokumentation, sämtliche Beispielprogramme und Bibliotheken, Daten, Teilelisten und eine Lötanleitung finden sich in den Weblinks.

Hardware

Der Hardware-Artikel befindet sich HIER.

Software

In diesem Artikel, der die Software für die tolle von Fabian designte Multi IO Projekt Platine vorstellt, darf ich (Dirk) mich austoben. Die vorgestellten Bibliotheken sind natürlich nur ein Vorschlag und sollen nur zur Anregung eigener Projekte und eigener Bibliotheken dienen. Es ist geplant, eine Bibliothek mit allen fest installierten Sensoren und Aktoren aufzubauen. Darüber hinaus soll sich eine weitere Bibliothek mit Umwelt-Fragen beschäftigen (Luftdruck, Luftfeuchtigkeit, Temperatur) sowie eine mit den Sensoren für Lageerkennung (GPS, 2D- oder 9D-Kompass). Diese Bibliotheken liegen – wie das gesamte Projekt – als Open Source vor und werden den Usern zugänglich gemacht.

RP6 M256 WIFI

Die M256-WiFi-Platine (= "M256") kann über den I2C-Bus alle I2C-Sensoren und I2C-Aktoren ansteuern und hat mit ihren vielen freien Ressourcen (Portpins) natürlich optimale Voraussetzungen, um die weiteren Funktionen der Multi IO Platine zu nutzen. Dazu wird sie (wenn alle Funktionen gleichzeitig genutzt werden sollen) mit drei Steckverbindungen angeschlossen:

- IO-Mxxx <-> IO_PWM/T2/T3

- ADC-Mxxx <-> ADC_IO2/CMP

- ADC-M256 <-> ADC_IO1

Dadurch ergeben sich umfangreiche Möglichkeiten, die Sensoren der Multi IO Platine auszulesen und Aktoren zu schalten. Die folgenden 3 Tabellen zeigen die Verbindungen:

Stecker IO-Mxxx:

| Stecker-Pin | M256-Port | M256-Funktion | Multi IO-Funktion | I/O |

| 1 | PE7 | ICP3 | DCF77 | I |

| 2 | GND | |||

| 3 | PE6 | T3 | SHARPS_PWR | O |

| 4 | PE5 | OC3C | SNAKE_SWITCH | O |

| 5 | PB4 | OC2A | BUZZER | O |

| 6 | PK7 | ADC15 | (TX *) | |

| 7 | PH6 | OC2B | SNAKE_KEY / (TX *) | I |

| 8 | PK6 | ADC14 | (RX *) | |

| 9 | PE4 | OC3B | LFS_PWR | O |

| 10 | VDD |

Zu *) UART nicht am IO_PWM/Tx/Ty Stecker der M256 vorhanden!

Stecker ADC-Mxxx:

| Stecker-Pin | M256-Port | M256-Funktion | Multi IO-Funktion | I/O |

| 1 | PK0 | ADC8 | TOUCH / LFS_L | I |

| 2 | GND | |||

| 3 | PK1 | ADC9 | 3V3 / LFS_M | I |

| 4 | PE3 | OC3A/AIN1 | BUMPER_L | I/O * |

| 5 | PK2 | ADC10 | LFS_R | I |

| 6 | GND | |||

| 7 | PK3 | ADC11 | BUTTONS | I |

| 8 | PE2 | XCK0/AIN0 | BUMPER_R | I/O * |

| 9 | PK4 | ADC12 | 3V3 alt.1 | I |

| 10 | VDD |

Zu *) Eingang für Bumper-Taster, Ausgang für Bumper-LED!

Stecker ADC-M256:

| Stecker-Pin | M256-Port | M256-Funktion | Multi IO-Funktion | I/O |

| 1 | PF1 | ADC1 | LDR1 | I |

| 2 | GND | GND | ||

| 3 | PF0 | ADC0 | LDR2 | I |

| 4 | VDD | |||

| 5 | PF2 | ADC2 | LFS_R1 | I |

| 6 | GND | GND | ||

| 7 | PF3 | ADC3 | LFS_L1 | I |

| 8 | GND | GND | ||

| 9 | PF4 | ADC4 | SHARP_L / 3V3 | I |

| 10 | GND | GND | ||

| 11 | PF5 | ADC5 | SHARP_R / TOUCH | I |

| 12 | PF6 | ADC6 | SNAKE_R | I |

| 13 | PF7 | ADC7 | SNAKE_L | I |

| 14 | GND | GND |

Multi IO Projekt Library

Diese Avr-gcc Library für das Multi IO Projekt Board (= "MultiIO") geht von folgenden Voraussetzungen aus:

- Die RP6v2 M256 WiFi Platine (= "M256") wird für die Ansteuerung der MultiIO benutzt (1).

- Die M256 ist der I2C-Bus Master.

- Die I2C-Bus Geschwindigkeit beträgt 100 kHz.

- Alle Hardware-Komponenten der MultiIO sind aufgebaut (2).

- Alle Jumper auf der MultiIO sind in ihrer Standardstellung (3).

- Die MultiIO und die M256 sind mit dem XBUS des RP6-Systems 1:1 verbunden.

- Der Wannenstecker IO_Mxxx der MultiIO ist mit dem Wannenstecker IO_PWM/T2/T3 der M256 1:1 verbunden.

- Der Wannenstecker ADC_Mxxx der MultiIO ist mit dem Wannenstecker ADC_IO2/CMP der M256 1:1 verbunden.

- Der Wannenstecker ADC_M256 der MultiIO ist mit dem Wannenstecker ADC_IO1 der M256 1:1 verbunden.

Zu (1): Dies soll nur der 1. Schritt sein. Natürlich ist die MultiIO auch

an die RP6 BASE, die M32 und die M128 des RP6-Systems und an

praktisch alle anderen Microcontroller-Plattformen anschließbar!

Zu (2): Wenn nicht alle Komponenten aufgebaut sind, sind die zugehörigen

Funktionen natürlich nicht funktionsfähig und können nicht benutzt

werden.

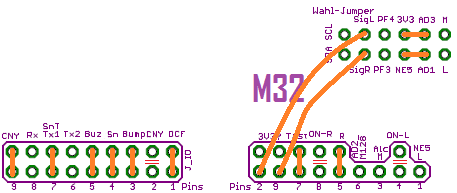

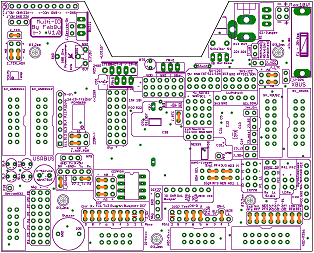

Zu (3): Siehe folgende Abbildung!

Standard-Jumperstellung für die M256

Hinweis: Die Jumper sind orange eingezeichnet!

Hinweis: Die Jumper sind orange eingezeichnet!

Die rote Doppellinie bedeutet: Hier NIE einen Jumper aufstecken!!! Die Jumper der Stromversorgung wurden nicht berücksichtigt!

Die Library (Software-Bibliothek) besteht aus drei Teilen:

- Dem Configuration Header -> Hier stehen alle Definitionen und Festlegungen, die der grundlegenden Konfiguration der MultiIO dienen. Diese Datei kann auf die eigenen Hardware-Voraussetzungen angepaßt werden, ohne dass die eigentliche Library (Header und Source) verändert werden muss.

- Dem Library Header -> Hier gibt es Definitionen, Variablen- und Funktionsdeklarationen für die Library.

- Der Library Source -> Das ist die eigentliche Library.

Configuration Header

Datei RP6M256_MultiIO.h:

/* * **************************************************************************** * RP6 ROBOT SYSTEM - RP6 CONTROL M256 Examples * **************************************************************************** * Example: RP6M256 MultiIO Library * Author(s): Dirk * **************************************************************************** * Description: * Configuration header file for new MultiIO Project Board library. * * **************************************************************************** */ #ifndef RP6M256_MULTIIO_H #define RP6M256_MULTIIO_H /*****************************************************************************/ // MultiIO hardwired components: // - I2C Voltage & Current Sensor (LTC2990) // - I2C Real Time Clock (RTC DS1307Z) // - I2C Temperature Sensor (TCN75A) // - I2C Servo Controller (PCA9685) // - I2C EEPROM (24LCXXX) // - 3V3 Voltage Sensor // - Touch Sensor (with NE555) // - Buttons // - LEDs // - Buzzer /*****************************************************************************/ // I2C Voltage & Current Sensor (LTC2990): #define I2C_MULTIIO_VCS_ADR 0x98 // ADR1/0 = 0/0 //#define I2C_MULTIIO_VCS_ADR 0x9a // ADR1/0 = 0/1 //#define I2C_MULTIIO_VCS_ADR 0x9c // ADR1/0 = 1/0 //#define I2C_MULTIIO_VCS_ADR 0x9e // ADR1/0 = 1/1 //#define I2C_MULTIIO_VCS_ADR 0xee // Global sync address // (Shunt resistor, current and voltage adjustment!) #define SHUNT_R 0.051 // R10 [Ohm] #define C_ADJUST 2.0 // Current adjust factor #define C_OFFSET 0.0 // Current offset [mA] #define VBAT_ADJUST 3.2 // (R13 + R14) / R14 #define VSERVO_ADJUST 2.5 // (R32 + R22) / R22 /*****************************************************************************/ // I2C Real Time Clock (RTC DS1307Z): #define I2C_MULTIIO_RTC_ADR 0xD0 // Default /*****************************************************************************/ // I2C Temperature Sensor (TCN75A): // (A1 always 0!) #define I2C_MULTIIO_TEMP_ADR 0x90 // A2/0 = 0/0 //#define I2C_MULTIIO_TEMP_ADR 0x92 // A2/0 = 0/1 //#define I2C_MULTIIO_TEMP_ADR 0x98 // A2/0 = 1/0 //#define I2C_MULTIIO_TEMP_ADR 0x9a // A2/0 = 1/1 /*****************************************************************************/ // I2C Servo Controller (PCA9685): // (A5, A4, A3, A2 always 0!) #define I2C_MULTIIO_SERVO_ADR 0x80 // A1/0 = 0/0 //#define I2C_MULTIIO_SERVO_ADR 0x82 // A1/0 = 0/1 //#define I2C_MULTIIO_SERVO_ADR 0x84 // A1/0 = 1/0 //#define I2C_MULTIIO_SERVO_ADR 0x86 // A1/0 = 1/1 //#define I2C_MULTIIO_SERVO_ADR 0xe0 // ALLCALLADR // (Servo power is connected to LED8 of the PCA9685!) #define CHSERVOPWR 9 // Servo left touch (LT), right touch (RT), middle position (MP) constants: // (Hints: - Servo impulse length [ms] = Servo position value / 204.8 // (Formula only valid for a PWM of 50 Hz!) // - Min. servo impulse (0,7 ms) = Servo position 143 // - Mid. servo impulse (1,5 ms) = Servo position 307 // - Max. servo impulse (2,3 ms) = Servo position 471 // - !!! You should NOT use servo position values < 143 or > 471 !!!) #define SERVO1_LT 205 // Servo impulse ~1ms #define SERVO1_RT 410 // Servo impulse ~2ms #define SERVO1_MP ((SERVO1_RT - SERVO1_LT) / 2 + SERVO1_LT) #define SERVO2_LT 205 #define SERVO2_RT 410 #define SERVO2_MP ((SERVO2_RT - SERVO2_LT) / 2 + SERVO2_LT) #define SERVO3_LT 205 #define SERVO3_RT 410 #define SERVO3_MP ((SERVO3_RT - SERVO3_LT) / 2 + SERVO3_LT) #define SERVO4_LT 205 #define SERVO4_RT 410 #define SERVO4_MP ((SERVO4_RT - SERVO4_LT) / 2 + SERVO4_LT) #define SERVO5_LT 205 #define SERVO5_RT 410 #define SERVO5_MP ((SERVO5_RT - SERVO5_LT) / 2 + SERVO5_LT) #define SERVO6_LT 205 #define SERVO6_RT 410 #define SERVO6_MP ((SERVO6_RT - SERVO6_LT) / 2 + SERVO6_LT) #define SERVO7_LT 205 #define SERVO7_RT 410 #define SERVO7_MP ((SERVO7_RT - SERVO7_LT) / 2 + SERVO7_LT) #define SERVO8_LT 205 #define SERVO8_RT 410 #define SERVO8_MP ((SERVO8_RT - SERVO8_LT) / 2 + SERVO8_LT) /*****************************************************************************/ // I2C EEPROM (24LCXXX): // (A2=1 not usable with 24LC1024-P!) #define I2C_MULTIIO_EEPROM_ADR 0xA0 // A2/1/0 = 0/0/0 //#define I2C_MULTIIO_EEPROM_ADR 0xA2 // A2/1/0 = 0/0/1 //#define I2C_MULTIIO_EEPROM_ADR 0xA4 // A2/1/0 = 0/1/0 //#define I2C_MULTIIO_EEPROM_ADR 0xA6 // A2/1/0 = 0/1/1 //#define I2C_MULTIIO_EEPROM_ADR 0xA8 // A2/1/0 = 1/0/0 //#define I2C_MULTIIO_EEPROM_ADR 0xAA // A2/1/0 = 1/0/1 //#define I2C_MULTIIO_EEPROM_ADR 0xAC // A2/1/0 = 1/1/0 //#define I2C_MULTIIO_EEPROM_ADR 0xAE // A2/1/0 = 1/1/1 // I2C-EEPROM storage capacity [kbit]: #define I2C_EEPROM_KBIT 32 // 24LC32-P <== Default //#define I2C_EEPROM_KBIT 64 // 24LC64-P //#define I2C_EEPROM_KBIT 128 // 24LC128-P //#define I2C_EEPROM_KBIT 256 // 24LC256-P //#define I2C_EEPROM_KBIT 512 // 24LC512-P //#define I2C_EEPROM_KBIT 1024 // 24LC1024-P // I2C-EEPROM pagesize [byte]: // ATTENTION: The pagesize must fit to the EEPROM type defined above! #define I2C_EEPROM_PAGESIZE 32 // EEPROM 32 or 64 kbit //#define I2C_EEPROM_PAGESIZE 64 // EEPROM 128 or 256 kbit //#define I2C_EEPROM_PAGESIZE 128 // EEPROM 512 kbit //#define I2C_EEPROM_PAGESIZE 256 // EEPROM 1024 kbit /*****************************************************************************/ // 3V3 Voltage Sensor: #define ADC_MULTIIO_3V3 ADC_9 // At ADC-Mxxx //#define ADC_MULTIIO_3V3 ADC_12 // At ADC-Mxxx //#define ADC_MULTIIO_3V3 ADC_4 // At ADC-M256 /*****************************************************************************/ // Touch Sensor (with NE555): #define ADC_MULTIIO_TOUCH ADC_8 // At ADC-Mxxx //#define ADC_MULTIIO_TOUCH ADC_5 // At ADC-M256 #define ADCVAL_NOTOUCH 15 #define ADCVAL_TOUCH 1020 #define ADCVAL_LIMIT_T ((ADCVAL_TOUCH - ADCVAL_NOTOUCH) / 2 + ADCVAL_NOTOUCH) /*****************************************************************************/ // Buttons: #define ADC_MULTIIO_BUTTONS ADC_11 // At ADC-Mxxx #define ADCVAL_BUTTON1 14 #define ADCVAL_BUTTON2 577 #define ADCVAL_BUTTON3 736 #define ADCVAL_BUTTON4 812 #define ADCVAL_LIMIT12 ((ADCVAL_BUTTON2 - ADCVAL_BUTTON1) / 2 + ADCVAL_BUTTON1) #define ADCVAL_LIMIT23 ((ADCVAL_BUTTON3 - ADCVAL_BUTTON2) / 2 + ADCVAL_BUTTON2) #define ADCVAL_LIMIT34 ((ADCVAL_BUTTON4 - ADCVAL_BUTTON3) / 2 + ADCVAL_BUTTON3) #define ADCVAL_LIMIT40 ((1023 - ADCVAL_BUTTON4) / 2 + ADCVAL_BUTTON4) /*****************************************************************************/ // LEDs: // (Status LED1..LED4 are connected to LED15..LED12 of the PCA9685!) #define CHLED1 16 #define CHLED2 15 #define CHLED3 14 #define CHLED4 13 /*****************************************************************************/ // Buzzer: // (This library assumes that the buzzer is connected to OC2A_PI4 (PB4). // This is the case, if you connect IO-Mxxx with IO_PWM/T2/T3 of the M256. // // Possible connections of the buzzer on the MultiIO Project Board: // // M256 plug: Portpin name: Portpin: // IO_PWM/T2/T3 OC2A_PI4 PB4 <== Default of THIS library! // IO_PWM/T0/T1 IO_OC0B PG5 // UART_SPI1/T5 IO_PL3_OC5A PL3 // UART_SPI2/T4 IO_PH5_OC4C PH5 // // You may of course use one of the other portpins (PG5, PL3, PH5) for the // buzzer, but then you will have to write your own buzzer functions!!! // Attention: Timer/Counter0 is used by the RP6M256 library, so you may NOT // use IO_OC0B (PG5) with hardware PWM!) /*****************************************************************************/ // Other ADC channel definitions: // (Depending on jumper settings on the MultiIO Project Board!) #define ADC_MULTIIO_LDR2 ADC_0 // At ADC-M256 #define ADC_MULTIIO_LDR1 ADC_1 // At ADC-M256 #define ADC_MULTIIO_LFS_R1 ADC_2 // At ADC-M256 #define ADC_MULTIIO_LFS_L1 ADC_3 // At ADC-M256 #define ADC_MULTIIO_SHARP_L ADC_4 // At ADC-M256 #define ADC_MULTIIO_SHARP_R ADC_5 // At ADC-M256 #define ADC_MULTIIO_SNAKE_R ADC_6 // At ADC-M256 #define ADC_MULTIIO_SNAKE_L ADC_7 // At ADC-M256 #define ADC_MULTIIO_LFS_L ADC_8 // At ADC-Mxxx #define ADC_MULTIIO_LFS_M ADC_9 // At ADC-Mxxx #define ADC_MULTIIO_LFS_R ADC_10 // At ADC-Mxxx // Other IO portpin definitions: // (Bumper/LEDs in-/outputs at the ADC-Mxxx plug!) #define IO_MULTIIO_BUMPER_R_IN IO_PE2_XCK0_AIN0 // At ADC-Mxxx #define IO_MULTIIO_BUMPER_R_DDR DDRE #define IO_MULTIIO_BUMPER_R_PIN PINE #define IO_MULTIIO_BUMPER_R_PORT PORTE #define IO_MULTIIO_BUMPER_L_IN IO_PE3_OC3A_AIN1 // At ADC-Mxxx #define IO_MULTIIO_BUMPER_L_DDR DDRE #define IO_MULTIIO_BUMPER_L_PIN PINE #define IO_MULTIIO_BUMPER_L_PORT PORTE // Other IO portpin definitions: // (Depending on the IO-Mxxx plug connection. Default: IO_PWM/T2/T3!) #define IO_MULTIIO_LFS_PWR_IN IO_PE4_OC3B_I4 // IO-Mxxx: IO_PWM/T2/T3 #define IO_MULTIIO_LFS_PWR_DDR DDRE #define IO_MULTIIO_LFS_PWR_PORT PORTE //#define IO_MULTIIO_LFS_PWR_IN OC1B_PI6 // IO-Mxxx: IO_PWM/T0/T1 //#define IO_MULTIIO_LFS_PWR_DDR DDRB //#define IO_MULTIIO_LFS_PWR_PORT PORTB //#define IO_MULTIIO_LFS_PWR_IN IO_PL4_OC5B // IO-Mxxx: UART_SPI1/T5 //#define IO_MULTIIO_LFS_PWR_DDR DDRL //#define IO_MULTIIO_LFS_PWR_PORT PORTL //#define IO_MULTIIO_LFS_PWR_IN IO_PH3_OC4A // IO-Mxxx: UART_SPI2/T4 //#define IO_MULTIIO_LFS_PWR_DDR DDRH //#define IO_MULTIIO_LFS_PWR_PORT PORTH #define IO_MULTIIO_SHARPS_PWR_IN IO_PE6_T3_I6 // IO-Mxxx: IO_PWM/T2/T3 #define IO_MULTIIO_SHARPS_PWR_DDR DDRE #define IO_MULTIIO_SHARPS_PWR_PORT PORTE //#define IO_MULTIIO_SHARPS_PWR_IN IO_PD6_T1 // IO-Mxxx: IO_PWM/T0/T1 //#define IO_MULTIIO_SHARPS_PWR_DDR DDRD //#define IO_MULTIIO_SHARPS_PWR_PORT PORTD //#define IO_MULTIIO_SHARPS_PWR_IN IO_PL2_T5 // IO-Mxxx: UART_SPI1/T5 //#define IO_MULTIIO_SHARPS_PWR_DDR DDRL //#define IO_MULTIIO_SHARPS_PWR_PORT PORTL //#define IO_MULTIIO_SHARPS_PWR_IN IO_PH7_T4 // IO-Mxxx: UART_SPI2/T4 //#define IO_MULTIIO_SHARPS_PWR_DDR DDRH //#define IO_MULTIIO_SHARPS_PWR_PORT PORTH #define IO_MULTIIO_SNAKE_SWITCH_IN IO_PE5_OC3C_I5 // IO-Mxxx: IO_PWM/T2/T3 #define IO_MULTIIO_SNAKE_SWITCH_DDR DDRE #define IO_MULTIIO_SNAKE_SWITCH_PORT PORTE //#define IO_MULTIIO_SNAKE_SWITCH_IN OC0A_OCM_PI7 // IO-Mxxx: IO_PWM/T0/T1 //#define IO_MULTIIO_SNAKE_SWITCH_DDR DDRB //#define IO_MULTIIO_SNAKE_SWITCH_PORT PORTB //#define IO_MULTIIO_SNAKE_SWITCH_IN IO_PD5_XCK1 // IO-Mxxx: UART_SPI1/T5 //#define IO_MULTIIO_SNAKE_SWITCH_DDR DDRD //#define IO_MULTIIO_SNAKE_SWITCH_PORT PORTD //#define IO_MULTIIO_SNAKE_SWITCH_IN IO_PH2_XCK2 // IO-Mxxx: UART_SPI2/T4 //#define IO_MULTIIO_SNAKE_SWITCH_DDR DDRH //#define IO_MULTIIO_SNAKE_SWITCH_PORT PORTH #define IO_MULTIIO_SNAKE_KEY_IN IO_PH6_OC2B // IO-Mxxx: IO_PWM/T2/T3 #define IO_MULTIIO_SNAKE_KEY_DDR DDRH #define IO_MULTIIO_SNAKE_KEY_PIN PINH //#define IO_MULTIIO_SNAKE_KEY_IN OC1A_PI5 // IO-Mxxx: IO_PWM/T0/T1 //#define IO_MULTIIO_SNAKE_KEY_DDR DDRB //#define IO_MULTIIO_SNAKE_KEY_PIN PINB //#define IO_MULTIIO_SNAKE_KEY_IN IO_PL5_OC5C // IO-Mxxx: UART_SPI1/T5 //#define IO_MULTIIO_SNAKE_KEY_DDR DDRL //#define IO_MULTIIO_SNAKE_KEY_PIN PINL //#define IO_MULTIIO_SNAKE_KEY_IN IO_PH4_OC4B // IO-Mxxx: UART_SPI2/T4 //#define IO_MULTIIO_SNAKE_KEY_DDR DDRH //#define IO_MULTIIO_SNAKE_KEY_PIN PINH #define IO_MULTIIO_DCF77_IN IO_PE7_ICP3_I7 // IO-Mxxx: IO_PWM/T2/T3 #define IO_MULTIIO_DCF77_DDR DDRE #define IO_MULTIIO_DCF77_PIN PINE //#define IO_MULTIIO_DCF77_IN IO_PD4_ICP1 // IO-Mxxx: IO_PWM/T0/T1 //#define IO_MULTIIO_DCF77_DDR DDRD //#define IO_MULTIIO_DCF77_PIN PIND //#define IO_MULTIIO_DCF77_IN IO_PL1_ICP5 // IO-Mxxx: UART_SPI1/T5 //#define IO_MULTIIO_DCF77_DDR DDRL //#define IO_MULTIIO_DCF77_PIN PINL //#define IO_MULTIIO_DCF77_IN IO_PL0_ICP4 // IO-Mxxx: UART_SPI2/T4 //#define IO_MULTIIO_DCF77_DDR DDRL //#define IO_MULTIIO_DCF77_PIN PINL /*****************************************************************************/ #endif /****************************************************************************** * Additional info * **************************************************************************** * Changelog: * * ---> changes are documented in the file "RP6M256_MultiIOLib.c" * * **************************************************************************** */ /*****************************************************************************/ // EOF

Library Header

Datei RP6M256_MultiIOLib.h:

/*

* ****************************************************************************

* RP6 ROBOT SYSTEM - RP6 CONTROL M256 Examples

* ****************************************************************************

* Example: RP6M256 MultiIO Library

* Author(s): Dirk

* ****************************************************************************

* Description:

* Header file for new MultiIO Project Board library.

*

* ****************************************************************************

*/

#ifndef RP6M256_MULTIIOLIB_H

#define RP6M256_MULTIIOLIB_H

/*****************************************************************************/

// MultiIO hardwired components:

// - I2C Voltage & Current Sensor (LTC2990)

// - I2C Real Time Clock (RTC DS1307Z)

// - I2C Temperature Sensor (TCN75A)

// - I2C Servo Controller (PCA9685)

// - I2C EEPROM (24LCXXX)

// - 3V3 Voltage Sensor

// - Touch Sensor (with NE555)

// - Buttons

// - LEDs

// - Buzzer

/*****************************************************************************/

// Includes:

#include "RP6M256Lib.h"

#include "RP6I2CmasterTWI.h"

#include "RP6M256_MultiIO.h"

/*****************************************************************************/

// I2C Voltage & Current Sensor (LTC2990):

// Registers:

#define LTC2990_STATUS 0

#define LTC2990_CONTROL 1

#define LTC2990_TRIGGER 2

#define LTC2990_TINT_MSB 4

#define LTC2990_TINT_LSB 5

#define LTC2990_V1_MSB 6

#define LTC2990_V1_LSB 7

#define LTC2990_V2_MSB 8

#define LTC2990_V2_LSB 9

#define LTC2990_V3_MSB 10

#define LTC2990_V3_LSB 11

#define LTC2990_V4_MSB 12

#define LTC2990_V4_LSB 13

#define LTC2990_VCC_MSB 14

#define LTC2990_VCC_LSB 15

// Status register bitmasks:

#define LTC2990_STATUS_DEFAULT 0

#define LTC2990_STATUS_BUSY 1

#define LTC2990_STATUS_TINT_READY 2

#define LTC2990_STATUS_V1V2_READY 4

#define LTC2990_STATUS_V2_READY 8

#define LTC2990_STATUS_V3V4_READY 16

#define LTC2990_STATUS_V4_READY 32

#define LTC2990_STATUS_VCC_READY 64

// Control register bitmasks:

#define LTC2990_CONTROL_DEFAULT 0

#define LTC2990_CONTROL_MULTIIO 0b01011010 // Mode V1-V2, V3, V4

// All measurements per mode

// Single acquisition

#define LTC2990_CONTROL_MODE02_DEFAULT 0

#define LTC2990_CONTROL_MODE34_DEFAULT 0

#define LTC2990_CONTROL_REPEAT_SINGLE 64

#define LTC2990_CONTROL_TEMP_FORMAT 128

extern double tint;

extern double cbat;

extern double vbat;

extern double vservo;

extern double vcc;

void LTC2990_write_cfg(uint8_t);

#define LTC2990_init() {LTC2990_write_cfg(LTC2990_CONTROL_MULTIIO);}

void LTC2990_run(void);

void LTC2990_read(void);

void LTC2990_calculate(void);

void LTC2990_measure(void);

/*****************************************************************************/

// I2C Real Time Clock (RTC DS1307Z):

// Registers:

#define DS1307_SECONDS 0

#define DS1307_MINUTES 1

#define DS1307_HOURS 2

#define DS1307_DAY 3

#define DS1307_DATE 4

#define DS1307_MONTH 5

#define DS1307_YEAR 6

#define DS1307_CONTROL 7

#define DS1307_RAM 8

// Control register bitmasks:

#define DS1307_CONTROL_DEFAULT 0

#define DS1307_CONTROL_RS0 1

#define DS1307_CONTROL_RS1 2

#define DS1307_CONTROL_SQWE 16

#define DS1307_CONTROL_OUT 128

enum RTCWEEKDAYS {

R_MO = 1, R_TU, R_WE, R_TH, R_FR, R_SA, R_SU

};

typedef struct {

uint16_t year; // Year

uint8_t month; // Month [1..12]

enum RTCWEEKDAYS weekday; // Weekday [1..7 = R_MO..R_SU]

uint8_t day; // Day [1..31]

} rtcdate_t;

rtcdate_t rtc_date;

typedef struct {

uint8_t dst; // Daylight-saving-time (time zone)

uint8_t hour; // Hour [0..23]

uint8_t minute; // Minute [0..59]

uint8_t second; // Second [0..59]

} rtctime_t;

rtctime_t rtc_time;

uint8_t BCD2DEC(uint8_t);

uint8_t DEC2BCD(uint8_t);

void DS1307_write_cfg(uint8_t);

void DS1307_init(void);

#define CALC_DST // Time zone will be calculated

void DS1307_read(void);

void DS1307_write(void);

uint8_t DS1307_readRAM(uint8_t);

void DS1307_writeRAM(uint8_t, uint8_t);

/*****************************************************************************/

// I2C Temperature Sensor (TCN75A):

// Registers:

#define TCN75_TEMP 0

#define TCN75_CONFIG 1

#define TCN75_HYST 2

#define TCN75_LIMIT 3

// Config register bitmasks:

#define TCN75_CONFIG_RUN 0 // Default

#define TCN75_CONFIG_SHUTDOWN 1

#define TCN75_CONFIG_COMP 0 // Default

#define TCN75_CONFIG_INT 2

#define TCN75_CONFIG_ALERT_LOW 0 // Default

#define TCN75_CONFIG_ALERT_HIGH 4

#define TCN75_CONFIG_FAULT_1 0 // Default

#define TCN75_CONFIG_FAULT_2 8

#define TCN75_CONFIG_FAULT_4 16

#define TCN75_CONFIG_FAULT_6 24

// Only for the TCN75A - high resolution and OneShot mode:

#define TCN75A_CONFIG_RES_9 0 // Default

#define TCN75A_CONFIG_RES_10 32 // 0b00100000

#define TCN75A_CONFIG_RES_11 64 // 0b01000000

#define TCN75A_CONFIG_RES_12 96 // 0b01100000

#define TCN75A_CONFIG_ONESHOT_DISABLED 0 // Default

#define TCN75A_CONFIG_ONESHOT 128 // 0b10000000

extern double temperature;

void TCN75_write_cfg(uint8_t);

#define TCN75_shutdown() {TCN75_write_cfg(TCN75_CONFIG_SHUTDOWN);}

#define TCN75_run(__CONFIG__) {TCN75_write_cfg(__CONFIG__);}

extern uint8_t temperature_low;

extern uint8_t temperature_high;

#define getTemperatureHigh() (temperature_high)

#define getTemperatureLow() (temperature_low)

void TCN75_read(void);

double TCN75_calculate(void);

double TCN75_measure(void);

/*****************************************************************************/

// I2C Servo Controller (PCA9685):

// Registers:

#define PCA9685_MODE1 0

#define PCA9685_MODE2 1

#define PCA9685_SUBADR1 2

#define PCA9685_SUBADR2 3

#define PCA9685_SUBADR3 4

#define PCA9685_ALLCALLADR 5

#define PCA9685_LED0_ON_L 6

#define PCA9685_LED0_ON_H 7

#define PCA9685_LED0_OFF_L 8

#define PCA9685_LED0_OFF_H 9

#define PCA9685_LED1_ON_L 10

#define PCA9685_LED1_ON_H 11

#define PCA9685_LED1_OFF_L 12

#define PCA9685_LED1_OFF_H 13

#define PCA9685_LED2_ON_L 14

#define PCA9685_LED2_ON_H 15

#define PCA9685_LED2_OFF_L 16

#define PCA9685_LED2_OFF_H 17

#define PCA9685_LED3_ON_L 18

#define PCA9685_LED3_ON_H 19

#define PCA9685_LED3_OFF_L 20

#define PCA9685_LED3_OFF_H 21

#define PCA9685_LED4_ON_L 22

#define PCA9685_LED4_ON_H 23

#define PCA9685_LED4_OFF_L 24

#define PCA9685_LED4_OFF_H 25

#define PCA9685_LED5_ON_L 26

#define PCA9685_LED5_ON_H 27

#define PCA9685_LED5_OFF_L 28

#define PCA9685_LED5_OFF_H 29

#define PCA9685_LED6_ON_L 30

#define PCA9685_LED6_ON_H 31

#define PCA9685_LED6_OFF_L 32

#define PCA9685_LED6_OFF_H 33

#define PCA9685_LED7_ON_L 34

#define PCA9685_LED7_ON_H 35

#define PCA9685_LED7_OFF_L 36

#define PCA9685_LED7_OFF_H 37

#define PCA9685_LED8_ON_L 38

#define PCA9685_LED8_ON_H 39

#define PCA9685_LED8_OFF_L 40

#define PCA9685_LED8_OFF_H 41

#define PCA9685_LED9_ON_L 42

#define PCA9685_LED9_ON_H 43

#define PCA9685_LED9_OFF_L 44

#define PCA9685_LED9_OFF_H 45

#define PCA9685_LED10_ON_L 46

#define PCA9685_LED10_ON_H 47

#define PCA9685_LED10_OFF_L 48

#define PCA9685_LED10_OFF_H 49

#define PCA9685_LED11_ON_L 50

#define PCA9685_LED11_ON_H 51

#define PCA9685_LED11_OFF_L 52

#define PCA9685_LED11_OFF_H 53

#define PCA9685_LED12_ON_L 54

#define PCA9685_LED12_ON_H 55

#define PCA9685_LED12_OFF_L 56

#define PCA9685_LED12_OFF_H 57

#define PCA9685_LED13_ON_L 58

#define PCA9685_LED13_ON_H 59

#define PCA9685_LED13_OFF_L 60

#define PCA9685_LED13_OFF_H 61

#define PCA9685_LED14_ON_L 62

#define PCA9685_LED14_ON_H 63

#define PCA9685_LED14_OFF_L 64

#define PCA9685_LED14_OFF_H 65

#define PCA9685_LED15_ON_L 66

#define PCA9685_LED15_ON_H 67

#define PCA9685_LED15_OFF_L 68

#define PCA9685_LED15_OFF_H 69

#define PCA9685_ALL_LED_ON_L 250

#define PCA9685_ALL_LED_ON_H 251

#define PCA9685_ALL_LED_OFF_L 252

#define PCA9685_ALL_LED_OFF_H 253

#define PCA9685_PRE_SCALE 254

#define PCA9685_TESTMODE 255

// Mode1 register bitmasks:

#define PCA9685_MODE1_ALLCALL 1

#define PCA9685_MODE1_SUB3 2

#define PCA9685_MODE1_SUB2 4

#define PCA9685_MODE1_SUB1 8

#define PCA9685_MODE1_SLEEP 16

#define PCA9685_MODE1_AI 32

#define PCA9685_MODE1_EXTCLK 64

#define PCA9685_MODE1_RESTART 128

// Mode2 register bitmasks:

#define PCA9685_MODE2_OUTNE01_DEFAULT 0

#define PCA9685_MODE2_OUTDRV 4

#define PCA9685_MODE2_OCH 8

#define PCA9685_MODE2_INVRT 16

#define F_PCA9685 25000000.0 // Int. Clock: 25 MHz

void PCA9685_init(uint16_t);

#define initServo(__FREQ__) {PCA9685_init(__FREQ__);}

void PCA9685_set(uint8_t, uint16_t);

#define setServo(__SERVO__,__POS__) {PCA9685_set(__SERVO__,__POS__);}

void PCA9685_shutdown(void);

void PCA9685_restart(void);

void setServoPower(uint8_t);

/*****************************************************************************/

// I2C EEPROM (24LCXXX):

uint8_t I2C_EEPROM_readByte(uint16_t memAddr);

void I2C_EEPROM_writeByte(uint16_t memAddr, uint8_t data);

void I2C_EEPROM_readBytes(uint16_t startAddr, uint8_t *buffer, uint8_t length);

void I2C_EEPROM_writeBytes(uint16_t startAddr, uint8_t *buffer, uint8_t length);

/*****************************************************************************/

// 3V3 Voltage Sensor:

extern uint16_t adc3v3;

extern double v3v3;

uint16_t get3V3Sensor(void);

double calculate3V3(void);

double measure3V3(void);

/*****************************************************************************/

// Touch Sensor (with NE555):

extern uint16_t adcTouch;

extern uint8_t touch;

uint8_t getTouch(void);

/*****************************************************************************/

// Buttons:

extern uint16_t adcButtons;

extern uint8_t releasedButtonNumber;

extern uint8_t pressedButtonNumber;

uint8_t getPressedButtonNumber(void);

uint8_t checkPressedButtonEvent(void);

uint8_t checkReleasedButtonEvent(void);

/*****************************************************************************/

// LEDs:

void setMultiIOLEDs(uint8_t leds);

void dimMultiIOLED(uint8_t led, uint16_t duty);

void setMultiIOLED1(uint8_t led);

void setMultiIOLED2(uint8_t led);

void setMultiIOLED3(uint8_t led);

void setMultiIOLED4(uint8_t led);

/*****************************************************************************/

// Buzzer:

// Define tone frequencies (well temperament):

// Great Octave

#define Tone_H 2 // 123Hz

// Small Octave

#define Tone_c 16 // 131Hz

#define Tone_cis 30 // 139Hz

#define Tone_d 42 // 147Hz

#define Tone_dis 54 // 156Hz

#define Tone_e 65 // 165Hz

#define Tone_f 76 // 175Hz

#define Tone_fis 86 // 185Hz

#define Tone_g 96 // 196Hz

#define Tone_gis 105 // 208Hz

#define Tone_a 113 // 220Hz

#define Tone_ais 121 // 233Hz

#define Tone_h 128 // 247Hz

// ' Octave

#define Tone_C1 136 // 262Hz

#define Tone_Cis1 142 // 277Hz

#define Tone_D1 149 // 294Hz

#define Tone_Dis1 155 // 311Hz

#define Tone_E1 160 // 330Hz

#define Tone_F1 166 // 349Hz

#define Tone_Fis1 171 // 370Hz

#define Tone_G1 175 // 392Hz

#define Tone_Gis1 180 // 415Hz

#define Tone_A1 184 // 440Hz

#define Tone_Ais1 188 // 466Hz

#define Tone_H1 192 // 494Hz

// '' Octave

#define Tone_C2 195 // 523Hz

#define Tone_Cis2 199 // 554Hz

#define Tone_D2 202 // 587Hz

#define Tone_Dis2 205 // 622Hz

#define Tone_E2 208 // 659Hz

#define Tone_F2 210 // 698Hz

#define Tone_Fis2 213 // 740Hz

#define Tone_G2 215 // 784Hz

#define Tone_Gis2 217 // 831Hz

#define Tone_A2 219 // 880Hz

#define Tone_Ais2 221 // 932Hz

#define Tone_H2 223 // 988Hz

// ''' Octave

#define Tone_C3 225 // 1047Hz

#define Tone_Cis3 227 // 1109Hz

#define Tone_D3 228 // 1175Hz

#define Tone_Dis3 230 // 1245Hz

#define Tone_E3 231 // 1319Hz

#define Tone_F3 233 // 1397Hz

#define Tone_Fis3 234 // 1480Hz

#define Tone_G3 235 // 1568Hz

#define Tone_Gis3 236 // 1661Hz

#define Tone_A3 237 // 1760Hz

#define Tone_Ais3 238 // 1865Hz

#define Tone_H3 239 // 1976Hz

// '''' Octave

#define Tone_C4 240 // 2093Hz

#define Tone_Cis4 241 // 2217Hz

#define Tone_D4 242 // 2349Hz

#define Tone_Dis4 242 // 2489Hz

#define Tone_E4 243 // 2637Hz

#define Tone_F4 244 // 2794Hz

#define Tone_Fis4 244 // 2960Hz

#define Tone_G4 245 // 3136Hz

#define Tone_Gis4 246 // 3322Hz

#define Tone_A4 246 // 3520Hz

#define Tone_Ais4 247 // 3729Hz

#define Tone_H4 247 // 3951Hz

// ''''' Octave

#define Tone_C5 248 // 4186Hz

void Buzzer_init(void);

void setBuzzerPitch(uint8_t);

void soundBuzzer(uint8_t, uint16_t, uint16_t);

#define buzzer(__PITCH__,__TIME__) {soundBuzzer(__PITCH__,__TIME__,0);}

/*****************************************************************************/

// MultiIO Project Board initialisation and shutdown:

void multiio_init(void);

void multiio_shutdown(void);

/*****************************************************************************/

#endif

/******************************************************************************

* Additional info

* ****************************************************************************

* Changelog:

*

* ---> changes are documented in the file "RP6M256_MultiIOLib.c"

*

* ****************************************************************************

*/

/*****************************************************************************/

// EOF

Library Source

Datei RP6M256_MultiIOLib.c:

/*

* ****************************************************************************

* RP6 ROBOT SYSTEM - RP6 CONTROL M256 Examples

* ****************************************************************************

* Example: RP6M256 MultiIO Library

* Author(s): Dirk

* ****************************************************************************

* Description:

*

* This is our new Library that contains basic routines and functions for

* accessing the hardwired components of the MultiIO Project Board.

*

* There are much more sensors, that may be connected to the MultiIO Project

* Board: Line following sensors (5x CNY70), bumpers, "Snake Vision board",

* LDRs, I2C air pressure sensor, I2C humidity sensor, DCF77 module,

* I2C IMU, I2C ultrasonic distance sensors, GPS module and more

* sensors connected to free ADCs and IOs and to the I2C bus.

* This library doesn't contain functions for these sensors, because they are

* not HARDWIRED to the MultiIO Project Board and may be connected OPTIONALLY.

*

* ****************************************************************************

*/

/*****************************************************************************/

// MultiIO hardwired components:

// - I2C Voltage & Current Sensor (LTC2990)

// - I2C Real Time Clock (RTC DS1307Z)

// - I2C Temperature Sensor (TCN75A)

// - I2C Servo Controller (PCA9685)

// - I2C EEPROM (24LCXXX)

// - 3V3 Voltage Sensor

// - Touch Sensor (with NE555)

// - Buttons

// - LEDs

// - Buzzer

/*****************************************************************************/

// Includes:

#include "RP6M256_MultiIOLib.h"

/*****************************************************************************/

// Variables:

uint8_t registerBuf[13];

/*****************************************************************************/

// I2C Voltage & Current Sensor (LTC2990):

/**

* Sends the configuration byte to a LTC2990.

*

* Input: Config byte for control register

*

* There is also a macro LTC2990_init(), which

* initializes the sensor to work in V1-V2, V3,

* V4 and Single Acquisition mode.

*

* Example:

* LTC2990_init();

*

*/

void LTC2990_write_cfg(uint8_t config)

{

I2CTWI_transmit2Bytes(I2C_MULTIIO_VCS_ADR, LTC2990_CONTROL, config);

}

uint8_t vcs_tint_low;

uint8_t vcs_tint_high;

uint8_t vcs_v1_low;

uint8_t vcs_v1_high;

uint8_t vcs_v2_low;

uint8_t vcs_v2_high;

uint8_t vcs_v3_low;

uint8_t vcs_v3_high;

uint8_t vcs_v4_low;

uint8_t vcs_v4_high;

uint8_t vcs_vcc_low;

uint8_t vcs_vcc_high;

/**

* Starts a Single Acquisition measurement.

*/

void LTC2990_run(void)

{

I2CTWI_transmit2Bytes(I2C_MULTIIO_VCS_ADR, LTC2990_TRIGGER, 0);

}

/**

* Reads all data registers of the voltage & current

* sensor (VCS).

* They are stored in the variables defined above.

*/

void LTC2990_read(void)

{

I2CTWI_transmitByte(I2C_MULTIIO_VCS_ADR, LTC2990_TINT_MSB);

I2CTWI_readBytes(I2C_MULTIIO_VCS_ADR, registerBuf, 12);

vcs_tint_high = registerBuf[0];

vcs_tint_low = registerBuf[1];

vcs_v1_high = registerBuf[2];

vcs_v1_low = registerBuf[3];

vcs_v2_high = registerBuf[4];

vcs_v2_low = registerBuf[5];

vcs_v3_high = registerBuf[6];

vcs_v3_low = registerBuf[7];

vcs_v4_high = registerBuf[8];

vcs_v4_low = registerBuf[9];

vcs_vcc_high = registerBuf[10];

vcs_vcc_low = registerBuf[11];

}

double tint; // Internal temperature

double cbat; // Current at 9V

double vbat; // Battery voltage 9V (BAT)

double vservo; // Servo voltage 5 .. 7.5V

double vcc; // Voltage 5V (VCC)

/**

* Calculates the temperature, voltage and current

* values by using the data read from the LTC2990

* with the function LTC2990_read(). The sensor is

* configured to work in V1-V2, V3, V4 and Single

* Acquisition mode.

* The result is stored in the double variables

* defined above.

*/

void LTC2990_calculate(void)

{

int16_t tmp;

double v2;

tmp = (((vcs_tint_high & 0x1f) << 8) + vcs_tint_low) << 3;

tmp = tmp / 8;

tint = tmp / 16.0; // Internal temperature [°C]

tmp = (((vcs_v2_high & 0x7f) << 8) + vcs_v2_low) << 1;

tmp = tmp / 2;

v2 = tmp * 0.01942;

v2 *= C_ADJUST; // Current adjust factor

cbat = v2 / SHUNT_R + C_OFFSET; // Battery current [mA]

tmp = ((vcs_v3_high & 0x3f) << 8) + vcs_v3_low;

vbat = tmp * 0.00030518; // Battery voltage [V]

vbat *= VBAT_ADJUST; // Voltage divider factor

tmp = ((vcs_v4_high & 0x3f) << 8) + vcs_v4_low;

vservo = tmp * 0.00030518; // Servo voltage [V]

vservo *= VSERVO_ADJUST; // Voltage divider factor

tmp = ((vcs_vcc_high & 0x3f) << 8) + vcs_vcc_low;

vcc = 2.5 + tmp * 0.00030518; // VCC [V]

}

/**

* Performs a complete measurement with the sensor

* configured to work in V1-V2, V3, V4 and Single

* Acquisition mode.

* The result is stored in the double variables

* defined above.

* This function is BLOCKING for about 200 ms!

* If you don't want a blocking measurement, you

* have to write your own function with a non

* blocking pause between starting measurement

* and reading the result or with another mode

* of operation (Repeated Acquisitions).

*/

void LTC2990_measure(void)

{

LTC2990_run(); // Start measurement

mSleep(200);

LTC2990_read(); // Read data

LTC2990_calculate(); // Calculate values

}

/*****************************************************************************/

// I2C Real Time Clock (RTC DS1307Z):

/**

* This function converts a BCD to a DEC value.

*

*/

uint8_t BCD2DEC(uint8_t bcd)

{

return ((bcd >> 4) * 10 + (bcd & 0x0f));

}

/**

* This function converts a DEC to a BCD value.

*

*/

uint8_t DEC2BCD(uint8_t dec)

{uint8_t units = dec % 10;

if (dec /= 10) {

return (units + (DEC2BCD(dec) << 4));

}

else {

return units;

}

}

/**

* Sends the configuration byte to a DS1307.

*

* Input: Config byte for control register

*

*/

void DS1307_write_cfg(uint8_t config)

{

I2CTWI_transmit2Bytes(I2C_MULTIIO_RTC_ADR, DS1307_CONTROL, config);

}

/**

* Initializes the DS1307 by resetting all registers.

* Only use this function ONCE for a DS1307 without or

* with empty backup battery!

*/

void DS1307_init(void)

{

uint8_t i;

for (i = 0; i < 8; i++) {

registerBuf[i] = 0;

}

I2CTWI_transmitBytes(I2C_MULTIIO_RTC_ADR, ®isterBuf[0], 8);

}

/**

* Reads all data registers of the Real Time Clock (RTC).

* They are stored in the time & date variables defined in

* the library header.

*/

void DS1307_read(void)

{

I2CTWI_transmitByte(I2C_MULTIIO_RTC_ADR, DS1307_SECONDS);

I2CTWI_readBytes(I2C_MULTIIO_RTC_ADR, registerBuf, 7);

rtc_time.second = BCD2DEC(registerBuf[0] & 0x7f);

rtc_time.minute = BCD2DEC(registerBuf[1]);

rtc_time.hour = BCD2DEC(registerBuf[2] & 0x3f);

rtc_date.weekday = registerBuf[3];

rtc_date.day = BCD2DEC(registerBuf[4]);

rtc_date.month = BCD2DEC(registerBuf[5]);

rtc_date.year = BCD2DEC(registerBuf[6]) + 2000;

rtc_time.dst = 0;

#ifdef CALC_DST

// Calculate MESZ (DST):

uint8_t wday = rtc_date.weekday; // Weekday [1..7 = R_MO..R_SU]

if(wday == 7) wday = 0;

if(rtc_date.month < 3 || rtc_date.month > 10) {

return;

}

if((rtc_date.day - wday >= 25)

&& (wday || rtc_time.hour >= 2)) {

if(rtc_date.month == 10)

return;

}

else {

if(rtc_date.month == 3) {

return;

}

}

rtc_time.dst = 1;

#endif

}

/**

* Writes the time & date infos in the variables defined in

* the library header to the Real Time Clock (RTC).

*/

void DS1307_write(void)

{

registerBuf[0] = DS1307_SECONDS;

registerBuf[1] = DEC2BCD(rtc_time.second);

registerBuf[2] = DEC2BCD(rtc_time.minute);

registerBuf[3] = DEC2BCD(rtc_time.hour);

registerBuf[4] = rtc_date.weekday;

registerBuf[5] = DEC2BCD(rtc_date.day);

registerBuf[6] = DEC2BCD(rtc_date.month);

registerBuf[7] = DEC2BCD(rtc_date.year - 2000);

I2CTWI_transmitBytes(I2C_MULTIIO_RTC_ADR, ®isterBuf[0], 8);

}

/**

* Reads and returns a data byte from the DS1307 RAM.

*

* Input: adr -> RAM address [0..55]

*

* Hints: - The real DS1307 RAM addresses are 8..63!

* - The RAM is nonvolatile. That means, that

* it keeps the data as long as the backup

* battery doesn't become weak!

*

*/

uint8_t DS1307_readRAM(uint8_t adr)

{

if (adr > 55) adr = 0;

I2CTWI_transmitByte(I2C_MULTIIO_RTC_ADR, (DS1307_RAM + adr));

return (I2CTWI_readByte(I2C_MULTIIO_RTC_ADR));

}

/**

* Writes a data byte to the DS1307 RAM.

*

* Input: adr -> RAM address [0..55]

* data -> Data byte [0..255]

*

* Hints: - The real DS1307 RAM addresses are 8..63!

* - The RAM is nonvolatile. That means, that

* it keeps the data as long as the backup

* battery doesn't become weak!

*

*/

void DS1307_writeRAM(uint8_t adr, uint8_t data)

{

if (adr > 55) adr = 0;

I2CTWI_transmit2Bytes(I2C_MULTIIO_RTC_ADR, (DS1307_RAM + adr), data);

}

/*****************************************************************************/

// I2C Temperature Sensor (TCN75A):

/**

* Sends the configuration byte to a TCN75A.

*

* Input: Config byte for config register

*

*/

void TCN75_write_cfg(uint8_t config)

{

I2CTWI_transmit2Bytes(I2C_MULTIIO_TEMP_ADR, TCN75_CONFIG, config);

}

uint8_t temperature_low;

uint8_t temperature_high;

/**

* Reads the two data registers of the temperature

* sensor.

* They are stored in the variables temperature_low

* and _high.

*

* Hint: Depending on the sensor configuration the

* data are located different in the two bytes

* - have a look at the datasheet!

*

*/

void TCN75_read(void)

{

I2CTWI_transmitByte(I2C_MULTIIO_TEMP_ADR, TCN75_TEMP);

I2CTWI_readBytes(I2C_MULTIIO_TEMP_ADR, registerBuf, 2);

temperature_low = registerBuf[0];

temperature_high = registerBuf[1];

}

double temperature; // Temperature [°C]

/**

* Calculates and returns the temperature value

* by using the data read from the TCN75A with

* the function TCN75_read(). The sensor is

* configured to Single Conversion and 12 bit

* measurement.

*/

double TCN75_calculate(void)

{

uint8_t templow;

double temp;

templow = getTemperatureLow();

if (templow & 128) // Calculate temperature

templow = (templow & 63) - 127;

else

templow = templow & 63;

temp = templow + (0.0625 * (getTemperatureHigh() >> 4));

return temp;

}

/**

* Performs a 12 bit measurement and returns the

* temperature [°C].

* This function is BLOCKING for about 250 ms!

* If you don't want a blocking measurement, you

* have to write your own function with a non

* blocking pause between starting measurement

* and reading the result or with another mode

* of operation (Continuous Conversion).

*/

double TCN75_measure(void)

{

TCN75_run(TCN75A_CONFIG_RES_12); // Start measurement

mSleep(250);

TCN75_shutdown(); // Stop measurement

TCN75_read(); // Read data

return (TCN75_calculate()); // Calculate value

}

/*****************************************************************************/

// I2C Servo Controller (PCA9685):

/**

* Call this once before using the servo function.

*

* Input: PWM frequency [40..1000 Hz]

*

* Hints: - Default servo frequency is 50 Hz!

* - The servo power is NOT switched on by

* this function!

*

* There is also a macro initServo(freq), which

* does exactly the same as this function.

*

* Example:

* initServo(50);

*

*/

void PCA9685_init(uint16_t freq)

{

if ((freq < 40) || (freq > 1000)) freq = 50;

I2CTWI_transmitByte(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE2);

uint8_t last_mode = I2CTWI_readByte(I2C_MULTIIO_SERVO_ADR);

last_mode &= ~PCA9685_MODE2_INVRT; // Clear INVRT bit

last_mode |= PCA9685_MODE2_OUTDRV; // Set OUTDRV bit

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE2, last_mode);

I2CTWI_transmitByte(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1);

last_mode = I2CTWI_readByte(I2C_MULTIIO_SERVO_ADR);

last_mode |= PCA9685_MODE1_AI; // Set AI bit

uint8_t mode1 = last_mode;

mode1 |= PCA9685_MODE1_SLEEP; // Set SLEEP bit

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1, mode1);

uint8_t prescale = (uint8_t) (F_PCA9685 / 4096 / freq - 0.5);

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_PRE_SCALE, prescale);

last_mode &= ~PCA9685_MODE1_SLEEP; // Clear SLEEP bit

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1, last_mode);

mSleep(1);

last_mode |= PCA9685_MODE1_RESTART; // Clear RESTART bit

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1, last_mode);

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_LED8_ON_H, 0x10);

return;

}

/**

* This is the servo position set function.

*

* Input: servo -> Servo number [1..8, 10..16]

* pos -> Servo position [SERVOx_LT..SERVOx_RT]

*

* Hints: - Servo number 9 cannot be set by this function!

* Please use setServoPower() function instead!

* - A servo position of 205 means 1 ms servo impulse,

* a position of 410 means a 2 ms servo impulse!

* You may calculate the servo impulse length by:

* ==> Impulse [ms] = servo position / 204.8 <==

* (Formula only valid for a PWM of 50 Hz!)

*

* There is also a macro setServo(servo, pos), which

* does exactly the same as this function.

*

* Example:

* setServo(2,300);

*

*/

void PCA9685_set(uint8_t servo, uint16_t pos)

{

if ((servo == 0) || (servo == CHSERVOPWR) || (servo > 16))

return;

uint8_t reg = servo * 4 + 4; // Register LEDx_OFF_L

I2CTWI_transmit3Bytes(I2C_MULTIIO_SERVO_ADR, reg, (pos & 0x00ff), (pos >> 8));

}

/**

* If the servos are not moving for a while, the

* servo function can be stopped with this

* function (PCA9685 set to sleep mode).

*

* Hint: The servo power is NOT switched off by

* this function!

*

*/

void PCA9685_shutdown(void)

{

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_ALL_LED_OFF_H, 0x10);

I2CTWI_transmitByte(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1);

uint8_t mode1 = I2CTWI_readByte(I2C_MULTIIO_SERVO_ADR);

mode1 |= PCA9685_MODE1_SLEEP; // Set SLEEP bit

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1, mode1);

}

/**

* If the servo function was stopped with the

* function PCA9685_shutdown() before, it can be

* (re)started again with this function.

*

* Hint: The servo power is NOT switched on by

* this function!

*

*/

void PCA9685_restart(void)

{

I2CTWI_transmitByte(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1);

uint8_t mode1 = I2CTWI_readByte(I2C_MULTIIO_SERVO_ADR);

if (mode1 & PCA9685_MODE1_RESTART) { // RESTART bit set?

mode1 &= ~PCA9685_MODE1_SLEEP; // Clear SLEEP bit

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1, mode1);

mSleep(1);

mode1 |= PCA9685_MODE1_RESTART; // Clear RESTART bit

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_MODE1, mode1);

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_ALL_LED_OFF_H, 0);

}

}

/**

* With this function you can switch the servo

* power on or off, if the servo power jumper on

* the board enables this feature.

*

* Input: pwr -> 0 (false) = servo power off

* >0 (true) = servo power on

*

* Hints: - If connected servos are not used, you

* should always switch the servo power off

* to save energy!

* - The PCA9685 is NOT restarted or put into

* shutdown mode by this function!

*

*/

void setServoPower(uint8_t pwr)

{

if (pwr > 0)

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_LED8_OFF_H, 0);

else

I2CTWI_transmit2Bytes(I2C_MULTIIO_SERVO_ADR, PCA9685_LED8_OFF_H, 0x10);

}

/*****************************************************************************/

// I2C EEPROM (24LCXXX):

// The following EEPROM types may be used:

// EEPROM Size: Chip Pagesize

// - 32 kbit: ST24LC32A 32

// - 64 kbit: ST24LC64 32

// - 128 kbit: ST24LC128 64

// - 256 kbit: ST24LC256 64

// - 512 kbit: ST24LC512 128

// - 1024 kbit: AT24LC1024 256

// ! You may choose the EEPROM type in the I2C EEPROM !

// ! section of the RP6M256_MultiIO.h file! !

/**

* Reads a single Byte from the EEPROM.

*/

uint8_t I2C_EEPROM_readByte(uint16_t memAddr)

{

uint8_t data;

I2CTWI_transmit2Bytes(I2C_MULTIIO_EEPROM_ADR, (memAddr >> 8), memAddr);

data = I2CTWI_readByte(I2C_MULTIIO_EEPROM_ADR);

return data;

}

/**

* Write a single data byte to the specified EEPROM address.

*/

void I2C_EEPROM_writeByte(uint16_t memAddr, uint8_t data)

{

I2CTWI_transmit3Bytes(I2C_MULTIIO_EEPROM_ADR, (memAddr >> 8), memAddr, data);

mSleep(5);

}

/**

* Reads "length" Bytes into the Buffer "buffer" from startAddr on.

* You can read the complete EEPROM into a buffer at once - if it is large enough.

* (But you only have 8KB SRAM on a MEGA2560 ;) )

* If "length" is higher than I2CTWI_BUFFER_REC_SIZE defined in RP6I2CmasterTWI.h,

* you have to adapt I2CTWI_BUFFER_REC_SIZE to the highest used "length" value!

*/

void I2C_EEPROM_readBytes(uint16_t startAddr, uint8_t *buffer, uint8_t length)

{

I2CTWI_transmit2Bytes(I2C_MULTIIO_EEPROM_ADR, (startAddr >> 8), startAddr);

I2CTWI_readBytes(I2C_MULTIIO_EEPROM_ADR, &buffer[0], length);

}

/**

* Write "length" Bytes from the Buffer to the EEPROM.

* YOU CAN ONLY WRITE MAXIMAL [I2C_EEPROM_PAGESIZE] BYTES AT ONCE!!!

* This is the Pagesize!

* You can NOT cross a page boundary!

* If (length + 2) is higher than I2CTWI_BUFFER_SIZE defined in RP6I2CmasterTWI.h,

* you have to adapt I2CTWI_BUFFER_SIZE to the highest used (length + 2) value!

*/

void I2C_EEPROM_writeBytes(uint16_t startAddr, uint8_t *buffer, uint8_t length)

{

uint8_t i, addrbuffer[length + 2];

addrbuffer[0] = (startAddr >> 8);

addrbuffer[1] = startAddr;

for(i = 0; i < length; i++) {

addrbuffer[i + 2] = buffer[i];

}

I2CTWI_transmitBytes(I2C_MULTIIO_EEPROM_ADR, &addrbuffer[0], (length + 2));

mSleep(5);

}

/*****************************************************************************/

// 3V3 Voltage Sensor:

uint16_t adc3v3; // 3V3 voltage sensor ADC value

/**

* This function reads and returns the ADC value of

* the 3V3 voltage sensor. The value is also stored

* in adc3v3.

*

*/

uint16_t get3V3Sensor(void)

{

adc3v3 = readADC(ADC_MULTIIO_3V3);

return adc3v3;

}

double v3v3; // 3V3 voltage [V]

/**

* Calculates and returns the 3.3V voltage value

* by using the data read from the 3V3 voltage

* sensor with the function get3V3Sensor().

*

*/

double calculate3V3(void)

{

return (5.0 / 1024.0 * adc3v3);

}

/**

* Measures and returns the 3.3V voltage value.

* The ADC value of the 3V3 voltage sensor is also

* stored in adc3v3.

*

*/

double measure3V3(void)

{

adc3v3 = readADC(ADC_MULTIIO_3V3);

return (5.0 / 1024.0 * adc3v3);

}

/*****************************************************************************/

// Touch Sensor (with NE555):

uint16_t adcTouch; // Touch sensor ADC value

uint8_t touch = 0; // True (1), if touched

/**

* Checks if the touch sensor antenna is touched - returns 1,

* if touched or 0, if the antenna is NOT touched.

*

*/

uint8_t getTouch(void)

{

adcTouch = readADC(ADC_MULTIIO_TOUCH);

if (adcTouch > ADCVAL_LIMIT_T) return 1;

else return 0;

}

/*****************************************************************************/

// Buttons:

uint16_t adcButtons; // Keypad ADC value

uint8_t releasedButtonNumber; // Released (last pressed) button

uint8_t pressedButtonNumber; // Actually pressed button

/**

* Checks which button is pressed - returns the button number,

* or 0, if no button is pressed.

* Maybe the values of ADCVAL_LIMITxx have to change because

* of variations in the resistors of the keypad! This is done

* in RP6M256_MultiIO.h, if you define other ADC values for

* your 4 buttons in ADCVAL_BUTTON1..ADCVAL_BUTTON4.

*

*/

uint8_t getPressedButtonNumber(void)

{

adcButtons = readADC(ADC_MULTIIO_BUTTONS);

if(adcButtons < 1020) {

nop();

nop();

nop();

adcButtons += readADC(ADC_MULTIIO_BUTTONS);

adcButtons >>= 1;

}

if(adcButtons < ADCVAL_LIMIT12)

return 1;

if(adcButtons < ADCVAL_LIMIT23)

return 2;

if(adcButtons < ADCVAL_LIMIT34)

return 3;

if(adcButtons < ADCVAL_LIMIT40)

return 4;

return 0;

}

/**

* This function has to be called frequently out of the

* main loop and checks if a button is pressed! It only returns

* the button number a single time, DIRECTLY when the button is

* pressed.

*

* This is useful for non-blocking keyboard check in the

* main loop. You don't need something like

* "while(getPressedButtonNumber());" to wait for the button

* to be released again!

*/

uint8_t checkPressedButtonEvent(void)

{

static uint8_t pressed_button = 0;

if(pressed_button) {

if(!getPressedButtonNumber())

pressed_button = 0;

}

else {

pressed_button = getPressedButtonNumber();

if(pressed_button)

return pressed_button;

}

return 0;

}

/**

* This function has to be called frequently out of

* the main loop and checks if a button is pressed AND

* released. It only returns the button number a single

* time, AFTER the button has been released.

*

* This is useful for non-blocking keyboard check in the

* main loop. You don't need something like

* "while(getPressedButtonNumber());" to wait for the button

* to be released again!

*/

uint8_t checkReleasedButtonEvent(void)

{

static uint8_t released_button = 0;

if(released_button) {

if(!getPressedButtonNumber()) {

uint8_t tmp = released_button;

released_button = 0;

return tmp;

}

}

else

released_button = getPressedButtonNumber();

return 0;

}

/*****************************************************************************/

// LEDs:

/**

* Set the 4 status LEDs of the MultiIO.

*

* Example:

* setMultiIOLEDs(0b1010);

* // this clears LEDs 1 and 3

* // and sets LEDs 2 and 4!

*

*/

void setMultiIOLEDs(uint8_t leds)

{

if (leds & 0b00000001) PCA9685_set(CHLED1, 4095);

else PCA9685_set(CHLED1, 0);

if (leds & 0b00000010) PCA9685_set(CHLED2, 4095);

else PCA9685_set(CHLED2, 0);

if (leds & 0b00000100) PCA9685_set(CHLED3, 4095);

else PCA9685_set(CHLED3, 0);

if (leds & 0b00001000) PCA9685_set(CHLED4, 4095);

else PCA9685_set(CHLED4, 0);

}

/**

* Dim the 4 status LEDs of the MultiIO.

*

* Input: led -> LED number [1..4]

* duty -> Duty cycle [0..4095]

*

* Example:

* dimMultiIOLED(2,2048);

* // this dims LED2 with a

* // duty cycle of 50% !

*

*/

void dimMultiIOLED(uint8_t led, uint16_t duty)

{

if (led == 1) PCA9685_set(CHLED1, duty);

if (led == 2) PCA9685_set(CHLED2, duty);

if (led == 3) PCA9685_set(CHLED3, duty);

if (led == 4) PCA9685_set(CHLED4, duty);

}

/**

* Set ONLY LED1, don't change anything for the other LEDs.

*

* Input: led -> 0 (false) = LED off

* >0 (true) = LED on

*

*/

void setMultiIOLED1(uint8_t led)

{

if (led > 0) PCA9685_set(CHLED1, 4095);

else PCA9685_set(CHLED1, 0);

}

/**

* Set ONLY LED2, don't change anything for the other LEDs.

*/

void setMultiIOLED2(uint8_t led)

{

if (led > 0) PCA9685_set(CHLED2, 4095);

else PCA9685_set(CHLED2, 0);

}

/**

* Set ONLY LED3, don't change anything for the other LEDs.

*/

void setMultiIOLED3(uint8_t led)

{

if (led > 0) PCA9685_set(CHLED3, 4095);

else PCA9685_set(CHLED3, 0);

}

/**

* Set ONLY LED4, don't change anything for the other LEDs.

*/

void setMultiIOLED4(uint8_t led)

{

if (led > 0) PCA9685_set(CHLED4, 4095);

else PCA9685_set(CHLED4, 0);

}

/*****************************************************************************/

// Buzzer:

/**

* Call this once before using the buzzer.

*

*/

void Buzzer_init(void)

{

DDRB |= OC2A_PI4; // Portpin: output

TCCR2A = 0;

TCCR2B = 0; // Sound off

PORTB &= ~OC2A_PI4; // Portpin low

}

/**

* This function has no timing stuff. It only sets the pitch

* and this can be used to generate tone sequences which

* would sound bad if the beeper turns of for a very short time

* in between - such as alarm tones or special melodies etc.

*

* Input: pitch -> 0 = sound off

* 1 = lowest frequency

* 255 = higest frequency

*

*/

void setBuzzerPitch(uint8_t pitch)

{

OCR2A = 255 - pitch;

if(pitch) {

TCCR2A = (1 << WGM21) | (1 << COM2A0);

TCCR2B = (1 << CS21) | (1 << CS22);

}

else {

TCCR2A = 0;

TCCR2B = 0; // Normal port operation

PORTB &= ~OC2A_PI4; // Portpin low

}

}

/**

* You can use this function to make the buzzer beep ;)

* This function is BLOCKING and generates a delay for the

* sound and a delay between two sounds.

*

* Input: pitch -> 0 = sound off

* 1 = lowest frequency

* 255 = higest frequency

* time -> sound length [ms]

* delay -> pause after the sound [ms]

*

* Example:

* soundBuzzer(150,50,25);

* soundBuzzer(200,50,25);

*

* There is also a macro buzzer(pitch, time). You may use

* it for sounds without a pause after the sound. The macro

* is BLOCKING during the sound length.

*

* Example:

* buzzer(150,50);

*

*/

void soundBuzzer(uint8_t pitch, uint16_t time, uint16_t delay)

{

setBuzzerPitch(pitch);

if (!pitch) return;

mSleep(time);

setBuzzerPitch(0); // Sound off

if (!delay) return;

mSleep(delay);

}

/*****************************************************************************/

/*****************************************************************************/

// MultiIO Project Board initialisation and shutdown:

/**

* You MUST call this function at the beginning of a

* main program, that uses the MultiIO Project Board.

*

*/

void multiio_init(void)

{

// Voltage & current sensor:

LTC2990_init(); // Init VCS

// Servo Controller:

PCA9685_init(50); // Init PWM 50 Hz

// Servo power:

setServoPower(0); // Servo power off

// Buzzer:

Buzzer_init(); // Init buzzer

}

/**

* If you don't use any function of the MultiIO

* Project Board, you can put the MultiIO into

* "SHUTDOWN MODE". In this mode the electric

* power consumption is very low to save energy.

*

*/

void multiio_shutdown(void)

{

// LEDs:

setMultiIOLEDs(0b0000); // MultiIO LEDs off

// Servo power:

setServoPower(0); // Servo power off

// Servo Controller:

PCA9685_shutdown(); // Shutdown PCA9685

// Temperature Sensor:

TCN75_shutdown(); // Shutdown TCN75A

}

/*****************************************************************************/

/*****************************************************************************/

/******************************************************************************

* Additional info

* ****************************************************************************

* Changelog:

* - v. 2.2 (shutdown mode added) 28.03.2013 by Dirk

* - v. 2.1 (LTC2990 current bug fixed) 26.03.2013 by Dirk

* - v. 2.0 (release for board V1.0) 17.02.2013 by Dirk

* - v. 1.0 (initial release) 21.01.2013 by Dirk

*

* ****************************************************************************

*/

/*****************************************************************************/

// EOF

Erklärung

Demo

makefile:

... TARGET = RP6M256_MultiIO_01 ... SRC += RP6M256_MultiIOLib.c ...

Datei RP6M256_MultiIO_01.c:

/*

* ****************************************************************************

* RP6 ROBOT SYSTEM - RP6 CONTROL M256 Examples

* ****************************************************************************

* Example: RP6M256 MultiIO

* Author(s): Dirk

* ****************************************************************************

* Description:

* In this example we show a first test for the MultiIO Project Board.

*

* ############################################################################

* The Robot does NOT move in this example! You can simply put it on a table

* next to your PC and you should connect it to the PC via the USB Interface!

* You should also connect to it via WIFI.

* ############################################################################

* ****************************************************************************

*/

/*****************************************************************************/

// Includes:

#include "RP6M256Lib.h" // The RP6 M256 Library.

// Always needs to be included!

#include "RP6I2CmasterTWI.h" // Include the I2C-Bus Master Library

/*****************************************************************************/

/*****************************************************************************/

// Include our new "RP6M256 MultiIO library":

// (This is the library for accessing the MultiIO Project Board!)

#include "RP6M256_MultiIOLib.h"

/*****************************************************************************/

/**

* Write a floating point number to the WIFI.

*

* Example:

*

* // Write a floating point number to the WIFI (no exponent):

* writeDouble_WIFI(1234567.890, 11, 3);

*

* The value of prec (precision) defines the number of decimal places.

* For 32 bit floating point variables (float, double ...) 6 is

* the max. value for prec (7 relevant digits).

* The value of width defines the overall number of characters in the

* floating point number including the decimal point. The number of

* pre-decimal positions is: (width - prec - 1).

*/

void writeDouble_WIFI(double number, uint8_t width, uint8_t prec)

{char buffer[width + 1];

dtostrf(number, width, prec, &buffer[0]);

writeString_WIFI(&buffer[0]);

}

/*****************************************************************************/

// I2C Error handler

/**

* This function gets called automatically if there was an I2C Error like

* the slave sent a "not acknowledge" (NACK, error codes e.g. 0x20 or 0x30).

*

*/

void I2C_transmissionError(uint8_t errorState)

{

writeString_P_WIFI("\nI2C ERROR - TWI STATE: 0x");

writeInteger_WIFI(errorState, HEX);

writeChar_WIFI('\n');

}

/*****************************************************************************/

// Main function - The program starts here:

int main(void)

{

initRP6M256(); // Always call this first! The Processor will not work

// correctly otherwise.

initLCD(); // Initialize the LC-Display (LCD)

// Always call this before using the LCD!

setLEDs(0b1111);

mSleep(500);

setLEDs(0b0000);

writeString_P_WIFI("\n\nRP6M256 Multi IO Selftest 1!\n");

// IMPORTANT:

I2CTWI_initMaster(100); // Initialize the TWI Module for Master operation

// with 100kHz SCL Frequency

// Register the event handler:

I2CTWI_setTransmissionErrorHandler(I2C_transmissionError);

setLEDs(0b1111);

// Write a text message to the LCD:

showScreenLCD("################", "################");

mSleep(1500);

showScreenLCD("RP6v2-M256-WIFI ", "Example Program");

mSleep(2500);

showScreenLCD("RP6M256 Multi IO", " Selftest 1");

mSleep(2500);

clearLCD();

setLEDs(0b0000);

// ---------------------------------------

uint8_t onoff = 0;

uint16_t servopos = SERVO1_LT;

startStopwatch1();

// IMPORTANT:

multiio_init(); // MultiIO init!!!

//setServoPower(1); // Servo power ON!

// ----------------------------------------------

// Set RTC once (battery empty or not existing:

rtc_time.second = 0;

rtc_time.minute = 0;

rtc_time.hour = 12; // 12:00

rtc_date.weekday = R_TH;

rtc_date.day = 28;

rtc_date.month = 3;

rtc_date.year = 2013; // Do, 28.3.2013

DS1307_write();

// Remove this, if RTC is set and running!!!

// ----------------------------------------------

// EEPROM test:

writeString_P_WIFI("\nWriting 128 to EEPROM address 5:\n");

I2C_EEPROM_writeByte(5, 128);

mSleep(500);

writeString_P_WIFI("Done!\n");

writeString_P_WIFI("\nReading EEPROM address 5:\n");

uint8_t tmp = I2C_EEPROM_readByte(5);

mSleep(500);

I2C_EEPROM_writeByte(5, 0);

writeString_P_WIFI("Done!\n");

writeString_P_WIFI("EEPROM address 5 content: ");

writeInteger_WIFI(tmp, DEC);

writeString_P_WIFI("\n");

// Buzzer test:

soundBuzzer(Tone_Cis2, 300, 200);

soundBuzzer(Tone_Fis2, 200, 100);

soundBuzzer(Tone_Ais2, 100, 100);

soundBuzzer(Tone_Dis3, 50, 100);

mSleep(1000);

soundBuzzer(Tone_Dis3, 300, 200);

soundBuzzer(Tone_Ais2, 200, 100);

soundBuzzer(Tone_Fis2, 100, 100);

soundBuzzer(Tone_Cis2, 50, 100);

while(true)

{

if(getStopwatch1() > 1000) // 1s

{

if (onoff) onoff = 0;

else onoff = 1;

// Buttons ADC test:

clearLCD();

pressedButtonNumber = getPressedButtonNumber();

setCursorPosLCD(0, 0);

writeStringLCD("Button: ");

writeIntegerLCD(pressedButtonNumber, DEC);

setCursorPosLCD(1, 0);

writeStringLCD("ADC: ");

writeIntegerLCD(adcButtons, DEC);

// 3V3 voltage sensor ADC test:

v3v3 = measure3V3();

writeString_WIFI("\n3V3 Voltage: ");

writeDouble_WIFI(v3v3, 4, 1);

writeString_WIFI("V\nADC 3V3: ");

writeInteger_WIFI(adc3v3, DEC);

// Touch sensor ADC test:

touch = getTouch();

if (touch) writeString_WIFI("\nTOUCHED!!!");

else writeString_WIFI("\nNOT touched.");

writeString_WIFI("\nADC Touch: ");

writeInteger_WIFI(adcTouch, DEC);

// Temperature sensor test:

temperature = TCN75_measure(); // Measure

writeString_WIFI("\nTemperature: ");

writeDouble_WIFI(temperature, 5, 1);

writeString_WIFI("°\n");

// Servo controller test:

// LEDs:

if (onoff) {

setMultiIOLED1(1);

setMultiIOLED2(0);

setMultiIOLED3(0);

setMultiIOLED4(1);

}

else

setMultiIOLEDs(0b0110);

// Servo 1:

setServo(1, servopos);

servopos += 10;

if (servopos > SERVO1_RT) servopos = SERVO1_LT;

// RTC test:

DS1307_read();

writeString_WIFI("RTC: ");

writeIntegerLength_WIFI(rtc_time.hour, DEC, 2);

writeString_WIFI(":");

writeIntegerLength_WIFI(rtc_time.minute, DEC, 2);

writeString_WIFI(":");

writeIntegerLength_WIFI(rtc_time.second, DEC, 2);

writeString_WIFI(" ");

writeIntegerLength_WIFI(rtc_date.day, DEC, 2);

writeString_WIFI(".");

writeIntegerLength_WIFI(rtc_date.month, DEC, 2);

writeString_WIFI(".");

writeIntegerLength_WIFI(rtc_date.year, DEC, 4);

writeString_WIFI("\n");

// Voltage & current sensor test:

LTC2990_measure();

writeString_WIFI("Temperature: ");

writeDouble_WIFI(tint, 5, 1);

writeString_WIFI("°\n");

writeString_WIFI("BAT Current: ");

writeDouble_WIFI(cbat, 6, 1);

writeString_WIFI("mA\nBAT Voltage: ");

writeDouble_WIFI(vbat, 4, 1);

writeString_WIFI( "V\nSERVO Volt.: ");

writeDouble_WIFI(vservo, 4, 1);

writeString_WIFI( "V\nVCC Voltage: ");

writeDouble_WIFI(vcc, 4, 1);

writeString_WIFI("V\n");

// MultiIO shutdown:

if (pressedButtonNumber == 4) {

writeString_WIFI("\nPress button 1 for MultiIO SHUTDOWN");

writeString_WIFI("\nor any other button to continue!!!\n");

do {

mSleep(1);

releasedButtonNumber = checkReleasedButtonEvent();

task_I2CTWI();

} while (!releasedButtonNumber);

if (releasedButtonNumber == 1) {

writeString_WIFI("\nPlease wait for MultiIO SHUTDOWN...\n");

multiio_shutdown();

mSleep(3000);

writeString_WIFI("\nThe MultiIO now is in SHUTDOWN MODE!!!\n");

mSleep(1000);

writeString_WIFI("\nRESET the M256 microcontroller now...\n\n");

while(true) {};

}

}

setStopwatch1(0);

}

task_I2CTWI();

}

return 0;

}

Erklärung

Linienfolger und Bumper Board Library

Diese Avr-gcc Library für das Linienfolger und das Bumper Board des Multi IO Projekts geht von folgenden Voraussetzungen aus:

- Die RP6v2 M256 WiFi Platine (= "M256") wird für die Ansteuerung der MultiIO benutzt.

- Die M256 ist der I2C-Bus Master.

- Die I2C-Bus Geschwindigkeit beträgt 100 kHz.

- Alle Jumper auf der MultiIO sind in ihrer Standardstellung (1).

- Die MultiIO und die M256 sind mit dem XBUS des RP6-Systems 1:1 verbunden.

- Der Wannenstecker IO_Mxxx der MultiIO ist mit dem Wannenstecker IO_PWM/T2/T3 der M256 1:1 verbunden.

- Der Wannenstecker ADC_Mxxx der MultiIO ist mit dem Wannenstecker ADC_IO2/CMP der M256 1:1 verbunden.

- Der Wannenstecker ADC_M256 der MultiIO ist mit dem Wannenstecker ADC_IO1 der M256 1:1 verbunden.

- Das Linienfolger und/oder das Bumper Board ist an den Stecker "CNY70" (P_CNY) bzw. "Bumper" (P_BUMPER) der MultiIO angeschlossen.

Zu (1): Siehe hier!

Linienfolger Sensoren (LFS) anschliessen

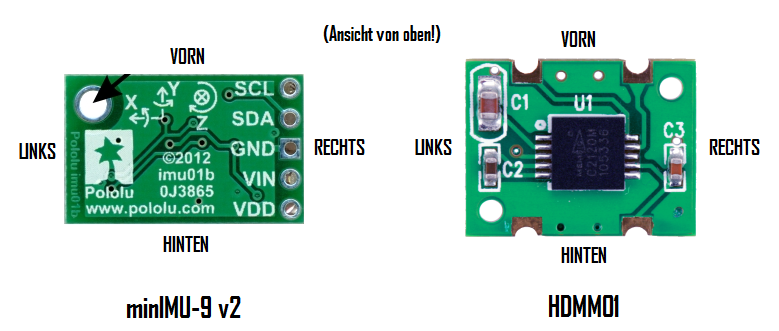

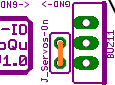

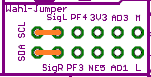

Will man die Linienfolger Sensoren (LFS) anstelle der 3,3V-Messung und des Touch Sensors nutzen (mit dieser Library für die M256), müssen Jumper auf der MultiIO umgesteckt werden. Die folgende Abbildung zeigt den Wahl-Jumper-Block:

I2C Sensoren (z.B. SRF02) anschliessen

Will man I2C Sensoren (z.B. SRF02) anstelle von analogen Sensoren (SHARP, Radar) auf dem Bumper Board nutzen (mit dieser Library für die M256), müssen Jumper auf der MultiIO umgesteckt werden. Die folgende Abbildung zeigt den Wahl-Jumper-Block:

Die Library (Software-Bibliothek) besteht aus zwei Teilen:

- Dem Library Header -> Hier gibt es Definitionen, Variablen- und Funktionsdeklarationen für die Library.

- Der Library Source -> Das ist die eigentliche Library.

Zusätzlich wird auch der MultiIO Configuration Header eingebunden. Hier stehen alle Definitionen und Festlegungen, die der grundlegenden Konfiguration der MultiIO dienen. Diese Datei kann auf die eigenen Hardware-Voraussetzungen angepaßt werden, ohne dass die eigentliche Library (Header und Source) verändert werden muss.

Library Header

Vor dem Kompilieren der Library muss eine Anpassung des Headers an die eigenen Hardware-Voraussetzungen erfolgen. Dazu gibt es im Header fünf Definitionen:

- LFS -> Linienfolger (= "LFS") Sensoren werden benutzt

- FIVE_SENSORS -> Es werden alle 5 LFS Sensoren (CNY70) benutzt (sonst nur 3!)

- BUMPERS -> Die Bumper werden verwendet

- SHARP_SENSORS -> Es werden analoge SHARP Sensoren benutzt ODER

- SRF02_SENSORS -> Es werden SRF02 Ultraschall Sensoren (I2C) benutzt

Im nachfolgenden Listing sind ALLE Definitionen aktiv. Dies muss an die eigene Hardware angepaßt werden. Wenn z.B. SRF02 NICHT benutzt werden, muss die Zeile mit "SRF02_SENSORS" auskommentiert werden. Dazu setzt man "//" an den Zeilenanfang. Beispiel:

//#define SRF02_SENSORS // SRF02 ultrasonic sensors are used

Datei: RP6M256_LFSBumperLib.h: