Dirk (Diskussion | Beiträge) K (→Anschluss-Schema) |

Dirk (Diskussion | Beiträge) K (→RP6 Xtra Module) |

||

| Zeile 407: | Zeile 407: | ||

Von den '''AREXX RP6 Xtra Modulen''' sind bei [http://www.conrad.de/ce/ CONRAD] für den RP6v2 erhältlich: | Von den '''AREXX RP6 Xtra Modulen''' sind bei [http://www.conrad.de/ce/ CONRAD] für den RP6v2 erhältlich: | ||

| − | * Arexx I2C GPS Empfänger JM3-GPS ([http://www.conrad.de/ce/de/product/1082385/Arexx-IC-GPS-Empfaenger-JM3-GPS 1082385]) | + | * Arexx [[RP6_Sensor_Board_und_Xtra_Module#I2C_GPS_Empf.C3.A4nger_JM3-GPS|I2C GPS Empfänger JM3-GPS]] ([http://www.conrad.de/ce/de/product/1082385/Arexx-IC-GPS-Empfaenger-JM3-GPS 1082385]) |

| − | * Arexx Gyro Modul JM3-GYRO ([http://www.conrad.de/ce/de/product/1082386/Arexx-Gyro-Modul-JM3-GYRO 1082386]) | + | * Arexx [[RP6_Sensor_Board_und_Xtra_Module#Gyro_Modul_JM3-GYRO|Gyro Modul JM3-GYRO]] ([http://www.conrad.de/ce/de/product/1082386/Arexx-Gyro-Modul-JM3-GYRO 1082386]) |

| − | * Arexx 3D Accelerometer Modul JM3-3DA ([http://www.conrad.de/ce/de/product/1082387/Arexx-3D-Accelerometer-Modul-JM3-3DA 1082387]) | + | * Arexx [[RP6_Sensor_Board_und_Xtra_Module#3D_Accelerometer_Modul_JM3-3DA|3D Accelerometer Modul JM3-3DA]] ([http://www.conrad.de/ce/de/product/1082387/Arexx-3D-Accelerometer-Modul-JM3-3DA 1082387]) |

===I2C GPS Empfänger JM3-GPS=== | ===I2C GPS Empfänger JM3-GPS=== | ||

Version vom 26. April 2014, 13:58 Uhr

Inhaltsverzeichnis

- 1 Was bisher geschah

- 2 Allgemein

- 3 RP6 Sensor Board

- 4 RP6 Xtra Module

- 5 Programmierung

- 6 Erfahrungsberichte

- 7 Siehe auch

- 8 Weblinks

- 9 Autoren

Was bisher geschah

Siehe auch "Was bisher geschah" im RP6v2 und im RP6 Artikel!

Mit, 27. Nov 2013 - Ankündigung einer Sensorerweiterungsplatine, die an die RP6v2-M256-WIFI angeschlossen werden kann

Sam, 22. Feb 2014 - Auslieferungsbeginn des RP6 Sensor Boards, des I2C GPS Empfängers, des 3D Accelerometer Moduls und des Gyro Moduls

Mon, 17. Mär 2014 - Das RP6 Sensor Board ist "nicht lieferbar", neuer Liefertermin angekündigt für den 12.06.2014 (!?)

Die, 25. Mär 2014 - Das RP6 Sensor Board ist wieder "sofort lieferbar"

Allgemein

Dieser Artikel beschreibt die Grundlagen und Programmierung des RP6 Sensor Boards und der RP6 Xtra Module. Dieses Erweiterungs-Modul und die Xtra Module sind Teile des RP6-Systems, das in den RN-Wissen-Artikeln RP6, RP6v2 und RP6 - Programmierung ausführlich beschrieben wird. Ausgegliedert aus den "Haupt-Artikeln" habe ich diese Module, da sie m.E. zu einer neuen "Ära" des RP6-Systems gehören:

Sie wurden nicht mehr von SlyD (Dominik S. Herwald) in Zusammenarbeit mit AREXX entwickelt, sondern nun von JM3 Engeneering (Dipl.-Ing. Jürgen Maisel). Ab Februar 2014 waren dann das RP6 Sensor Board RP6-JM03-61 (1082384) und die drei RP6 Xtra Module I2C GPS Empfänger JM3-GPS (1082385), Gyro Modul JM3-GYRO (1082386) und 3D Accelerometer Modul JM3-3DA (1082387) bei CONRAD lieferbar. Einen ersten Eindruck vom Sensor Board kann man im RoboterNetz und AREXX Support Forum bekommen,- siehe unter Weblinks!

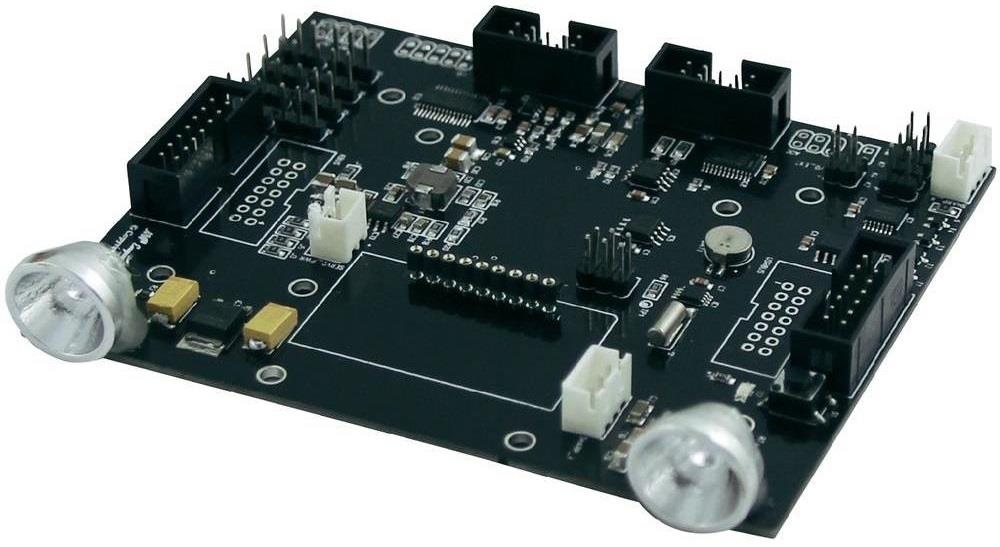

RP6 Sensor Board

Das RP6 Sensor Board gehört zu den "Erweiterungs-Modulen" des RP6-Systems. Andere "Erweiterungs-Module" werden im RP6v2 und im RP6 Artikel beschrieben!

Das RP6 Sensor Board ist das erste "Erweiterungs-Modul", das nicht über einen eigenen Microprozessor verfügt,- es ist also ein passives Modul, das von einem Microprozessor-System (z.B. RP6v2, M32, M128, M256 Wifi) angesteuert werden muss. Es ist ebenfalls das erste Modul, das nicht mehr über die rautenförmige Einbuchtung an der Vorderkante verfügt, sondern komplett rechteckig ist. Damit passt es (montiert auf den Standard-Abstandbolzen) nur auf den vorderen Platinenstapel 1 des RP6.

RP6 Xtra Module

Die RP6 Xtra Module gehören zu den "Zubehör- und Ersatzteilen" des RP6-Systems. Über die weiteren "Zubehör- und Ersatzteile" zum RP6 informiert der entsprechende Abschnitt im RP6v2 und im RP6 Artikel!

Die RP6 Xtra Module unterscheiden sich von den weiteren "Zubehör- und Ersatzteilen" dadurch, dass sie selbstständige Sensor-Platinen sind, die ideal zum RP6-System passen, aber auch mit anderen Microcontroller-Plattformen nutzbar sind.

RP6 Sensor Board

Das RP6 Sensor Board RP6-JM03-61 (1082384) wurde am 27.11.2013 von SlyD angekündigt (siehe Weblink!).

Beschreibung

(Laut Online-Katalog der Firma CONRAD!)

"Das RP6 Sensor Board erweitert die Möglichkeiten aller RP6 Roboter um wesentliche Sensorsignale für Robotik-Anwendungen wie zum Beispiel Dreharten (Yaw-Gyro), Kipp- und Neigewinkel, Kompassrichtung oder aber auch Zeit und Datum. Sie können einfach mit zusätzlichen Sharp Sensoren Abstände genau messen, z.B. für autonome Fahrrouten oder falls der Sensor nach unten gerichtet ist, kann er Treppenstufen oder ähnliches entdecken. Außerdem gibt es die Möglichkeit z.B. die Sharp Sensoren ein- bzw. auszuschalten um Strom zu sparen. Zusätzlich können bis zu 8 Servos angesteuert werden um z.B. einen Roboterarm zu bewegen, der auch mechanisch einfach zu montieren ist. Um die Möglichkeiten des RP6 Sensor Boards komplett ausnutzen zu können, wird ein RP6V2 und RP6Wifi Control Board empfohlen. Die ermöglicht den Roboter über Wifi fernzusteuern oder Sensordaten auf dem Kommandozentrum (PC) z.B Kompassdaten, Temperatur oder Kipp- und Neigewinkel anzeigen zu lassen."

Ausstattung

- Magnetometer- und Accelerometer für Kompassfunktion

- Gyro Sensor (Yaw)

- Sharp-Sensor Schnittstelle

- LED Scheinwerfer

- LED Treiber mit Smart Funktionen

- I²C Bus mit max. 400 kHz Übertragungsrate; Hot Swap I²C-Bus Buffer

- Taster mit LED

- Echtzeit-Uhr RTC

- Backupbatterie (Aufladung während des Betriebs)

- Expansion Port z.B. für GPS-I²C Bus Modul

- 8 Servo-Ausgänge mit eigenem Schaltregler

- 8 PWM Ausgänge

- 5 LED Ausgänge und 2 Digital-I/O Ausgänge.

Lieferumfang

- RP6 Sensor Board

- Montage-Kit

- Kabel

- Anleitung und CD mit Dokumentation.

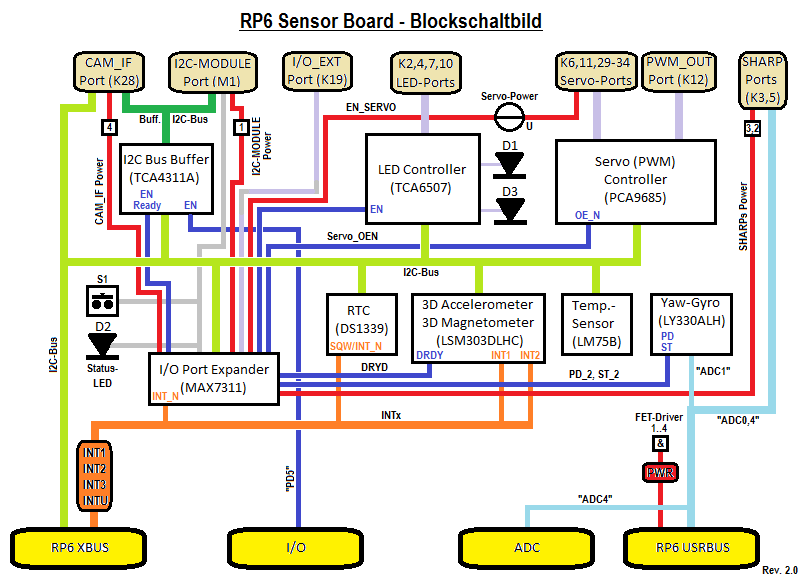

Blockschaltbild

Technische Daten

| Mikrocontroller: | kein |

| Speicher: | kein |

| Programmierung: | C++ (GCC, u.a.) über externes µC-System |

| Vorhandene Sensoren: | Temperatur, 3D Magnetfeld (Kompass), 3D Beschleunigung, Yaw-Gyro |

| Vorhandene Aktoren: | LED Controller (2 LEDs on board, 5 freie LED Ports), Status LED, Button, Servo (PWM) Controller für 8 Servos und 8 PWM-Kanäle, Real Time Clock (RTC), 2 freie I/O Ports |

| Abmessungen: | (L × B × H) 112 × 90 × 19 mm (B + 5 mm durch Scheinwerfer vorn) |

| Ausführung: | Fertig aufgebautes Erweiterungsmodul |

| Stromversorgung: | 6 AA NiMH Akkus (über die RP6v2 Base) und optionaler Zusatzakku 7,2..10 V für Servo Power |

| Hersteller: | Arexx Niederlande |

Umbau-Optionen

USRBUS- und XBUS-Wannenstecker

Der zweite Wannenstecker für den XBUS und USRBUS kann nachbestückt werden. Man braucht dazu:

- 2 Wannenstecker 2x5-polig gerade RM 2,54mm (CONRAD 741648)

Die Wannenstecker lötet man auf die eingezeichneten Positionen.

USRBUS-Belegung:

| Stecker-Pin | USRBUS | Sensor Board-Funktion | Verwendung | I/O |

| 1 | Y1 | "ADC0" | SHARP vorn | I |

| 2 | Y2 | "ADC1" | Yaw-Gyro | I |

| 3 | Y3 | PWR | Power für SHARPs, CAM_IF, I2C-MODULE |

O |

| 4 | Y4 | keine | ||

| 5 | Y5 | "ADC4" | SHARP hinten | I |

| 6..14 | Y6..Y14 | keine |

XBUS-Belegung:

| Stecker-Pin | XBUS | M256-Port | M256-Funktion | Sensor Board-Funktion | Jumper | Verwendung | I/O |

| 1 | GND | GND | GND | ||||

| 2 | GND | GND | GND | ||||

| 3 | VDD | VDD | VDD_1 | VDD +5V | |||

| 4 | +UB | +UB | VSS_1 | CAM_IF Power | |||

| 5 | VDD | VDD | VDD_1 | VDD +5V | |||

| 6 | +UB | +UB | VSS_1 | CAM_IF Power | |||

| 7 | INTU | PJ4 | PCINT13 | INTU | keine | I | |

| 8 | INT1 | PJ3 | PCINT12 | INT1 | 3 | LSM303DLHC: INT1 | I |

| 9 | INT3 | PJ5 | PCINT14 | INT3 | 2 5 |

DS1339: SQW/INT_N LSM303DLHC: INT2 |

I I |

| 10 | SCL | PD0 | SCL | SCL_M | I2C-Bus | O | |

| 11 | INT2 | PJ6 | PCINT15 | INT2 | 4 | MAX7311: INT_N | I |

| 12 | SDA | PD1 | SDA | SDA_M | I2C-Bus | I/O | |

| 13 | MRESET | MRESET | MRESET | keine | |||

| 14 | GND | GND | GND |

I/O-Patchfield_1

Dieses 10-polige "Patchfield_1", beschriftet mit "I/O" liegt neben dem Wannenstecker I/O und weist dieselbe Belegung auf. Möchte man auf dem Sensor Board Verbindungen über den Wannenstecker I/O zu einer angeschlossenen Microprozessor-Platine herstellen, dann kann man auf das "Patchfield_1" eine Stiftleiste löten. Man braucht dazu:

- 2-reihige Stiftleiste RM 2,54mm (z.B. 2x40-polig 741306)

Man trennt von der 2-reihigen Stiftleiste 2x5 Kontakte ab und lötet sie auf die Lötpunkte "I/O". Zuvor muss man u.U. Lötzinnreste aus den Lötpunkten mit Entlötlitze bzw. Entlötsaugpumpe entfernen.

Stecker I/O an M256 IO_PWM/T0/T1:

| Stecker-Pin | M256-Port | M256-Funktion | Sensor Board-Funktion | Verwendung | I/O |

| 1 | PD4 | ICP1 | keine | ||

| 2 | GND | keine | |||

| 3 | PD6 | T1 | keine | ||

| 4 | PB7 | OC0A | keine | ||

| 5 | PG5 | OC0B | keine | ||

| 6 | PD7 | T0 | keine | ||

| 7 | PB5 | OC1A | keine | ||

| 8 | PK5 | ADC13 | keine | ||

| 9 | PB6 | OC1B | "PD5" | I2C Bus Buffer Enable | O |

| 10 | VDD | keine |

ADC-Patchfield_2

Dieses 10-polige "Patchfield_2", beschriftet mit "ADC" liegt neben dem Wannenstecker ADC und weist dieselbe Belegung auf. Möchte man auf dem Sensor Board Verbindungen über den Wannenstecker ADC zu einer angeschlossenen Microprozessor-Platine herstellen, dann kann man auf das "Patchfield_2" eine Stiftleiste löten. Man braucht dazu:

- 2-reihige Stiftleiste RM 2,54mm (z.B. 2x40-polig 741306)

Man trennt von der 2-reihigen Stiftleiste 2x5 Kontakte ab und lötet sie auf die Lötpunkte "ADC".

Stecker ADC an M256 ADC_IO2/CMP:

| Stecker-Pin | M256-Port | M256-Funktion | Sensor Board-Funktion | Jumper | Verwendung | I/O |

| 1 | PK0 | ADC8 | keine | |||

| 2 | GND | keine | ||||

| 3 | PK1 | ADC9 | "ADC4" | 6 | SHARP hinten | I |

| 4 | PE3 | OC3A/AIN1 | keine | |||

| 5 | PK2 | ADC10 | keine | |||

| 6 | GND | keine | ||||

| 7 | PK3 | ADC11 | keine | |||

| 8 | PE2 | XCK0/AIN0 | keine | |||

| 9 | PK4 | ADC12 | keine | |||

| 10 | VDD | keine |

Anschluss-Optionen

I2C-MODULE

I2C-MODULE-Belegung:

| Stecker-Pin | Sensor Board -Funktion (M1) |

Verwendung | I/O | I2C GPS Empfänger -Funktion (K1) | |

| 1 | VCC | +5V | VCC_1 | ||

| 2 | SCLOUT | Buffered I2C-Bus | O | SCL/SCK | |

| 3 | SDAOUT | Buffered I2C-Bus | I/O | SDA/MOSI | |

| 4 | NC | keine | keine | ||

| 5 | I/O1 | Status LED | O | keine | |

| 6 | I/O2 | Taster | I | keine | |

| 7 | NC | keine | keine | ||

| 8 | GND | GND (geschaltet!) | GND | ||

| 9 | GND | GND (geschaltet!) | GND |

CAM_IF

CAM_IF-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K28) |

Verwendung | I/O |

| 1 | GND | GND (geschaltet!) | |

| 2 | VSS_1 | +7,2..10V (RP6: +UB) | |

| 3 | SCLOUT | Buffered I2C-Bus | O |

| 4 | SDAOUT | Buffered I2C-Bus | I/O |

| 5 | SCL_M | I2C-Bus | O |

| 6 | SDA_M | I2C-Bus | I/O |

IO_EXT

IO_EXT-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K19) |

Verwendung | I/O |

| 1 | MAX7311: I/O1.2 | freier I/O Port | I/O |

| 2 | GND | ||

| 3 | MAX7311: I/O1.1 | freier I/O Port | I/O |

| 4 | GND |

PWM_OUT

PWM_OUT-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K12) |

Verwendung | I/O |

| 1 | PCA9685: PWM0 | freier PWM Port | O |

| 2 | PCA9685: PWM1 | freier PWM Port | O |

| 3 | PCA9685: PWM2 | freier PWM Port | O |

| 4 | PCA9685: PWM3 | freier PWM Port | O |

| 5 | PCA9685: PWM4 | freier PWM Port | O |

| 6 | PCA9685: PWM5 | freier PWM Port | O |

| 7 | PCA9685: PWM6 | freier PWM Port | O |

| 8 | PCA9685: PWM7 | freier PWM Port | O |

TP1

Am Testpunkt TP1 kann man das Signal SQW/INT_N der RTC (DS1339) prüfen/messen.

LEDs

Rücklichter

Rücklichter-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K10) |

Verwendung | I/O |

| 1 | TCA6507: P3 | Rücklicht rechts | O |

| 2 | TCA6507: P4 | Rücklicht links | O |

Display-Hintergrundbeleuchtung

Display-Hintergrundbeleuchtung-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K7) |

Verwendung | I/O |

| 1 | TCA6507: P0 | Display-Hintergrundbeleuchtung | O |

| 2 | VDD_1 | +5V |

Freie Ausgänge

Freier Ausgang 1-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K4) |

Verwendung | I/O |

| 1 | TCA6507: P1 | freier LED Port | O |

| 2 | VDD_1 | +5V |

Freier Ausgang 2-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K2) |

Verwendung | I/O |

| 1 | TCA6507: P2 | freier LED Port | O |

| 2 | VDD_1 | +5V |

SHARP Sensoren

Vorn

Vorn-Belegung:

| Stecker-Pin | RP6v2-Port | RP6v2-Funktion | Sensor Board -Funktion (K5) |

Verwendung | I/O |

| 1 | PA0 | ADC0 | "ADC0" | SHARP vorn | I |

| 2 | VDD_1 | +5V | |||

| 3 | GND | GND (geschaltet!) |

Hinten

Hinten-Belegung:

| Stecker-Pin | M256-Port | M256-Funktion | Sensor Board -Funktion (K3) |

Verwendung | I/O |

| 1 | PK1 | ADC9 | "ADC4" | SHARP hinten | I |

| 2 | VDD_1 | +5V | |||

| 3 | GND | GND (geschaltet!) |

Servos

Power

SERVO_PWR-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K1) |

Verwendung |

| 1 | GND_POWER | Servo Power GND |

| 2 | VSS_POWER | Servo Power Eingang +7,2..10V |

Stecker

SERVO_1..7-Belegung:

| Stecker-Pin | Sensor Board -Funktion (K6,11,29..34) |

Verwendung | I/O |

| 1 | PCA9685: PWM15..8 | Servo Signal | O |

| 2 | Servo_PWR | Servo Power +5V (geschaltet!) | |

| 3 | GND_POWER | Servo Power GND |

Roboterarm RA2-HOBBY

RP6 Xtra Module

Von den AREXX RP6 Xtra Modulen sind bei CONRAD für den RP6v2 erhältlich:

- Arexx I2C GPS Empfänger JM3-GPS (1082385)

- Arexx Gyro Modul JM3-GYRO (1082386)

- Arexx 3D Accelerometer Modul JM3-3DA (1082387)

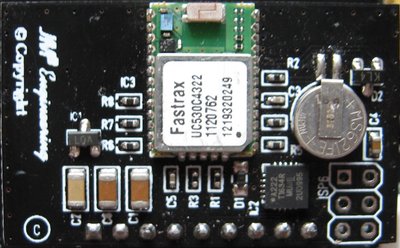

I2C GPS Empfänger JM3-GPS

(Laut Online-Katalog der Firma CONRAD!)

"Universelles GPS-I²C-Bus Modul für RP6 Roboter. Der GPS Empfänger stellt die NMEA-0183 Datensätze GGA, RMC, GSA und VTG in den veschiedenen Registern zur Verfügung. Damit ist eine einfache Weiterverarbeitung möglich."

Beschreibung

Der I2C GPS Empfänger ist eine kleine (38 x 23 mm) Zusatzplatine (RP6 Xtra Modul), die direkt auf das RP6 Sensor Board aufgesteckt werden kann. Sie kann aber auch überall eingesetzt werden, wo eine stabilisierte 5V Versorgungsspannung und ein 5V-I2C-Bus bis 400 kHz zur Verfügung steht.

Die Platine ist bestückt mit dem "Fastrax GPS antenna module" UC530. Als Backup-Batterie dient eine wieder aufladbare Lithium-Batterie (MS621FE). Zur Kommunikation zwischen dem UC530 und dem I2C-Bus ist ein ATtiny1634 an Bord, der auch die Auswertung des NMEA Protokolls übernimmt. Die 3,3 V Versorgungsspannung wird auf der Platine durch einen Spannungsregler (LM3480IM3-3.3) erzeugt. Über den I2C-Bus können folgende Daten der NMEA-0183 Datensätze GGA, RMC, GSA und VTG auf einfache Weise gelesen werden:

- Geograf. Breite

- Geograf. Länge

- GPS Status

- HDOP

- Satellitenzahl

- Kurs

- Geschwindigkeit

- Höhe

- UTC-Zeit

- Datum

- PDOP

- VDOP

- Satellit 1..12

Der ATtiny1634 ist natürlich vorprogrammiert, kann aber über eine vorbereitete 6-polige ISP-Schnittstelle auf der Platine auch umprogrammiert werden.

Lieferumfang

- I2C GPS Empfänger

- CD mit Anleitung und Software-Beispielen.

Technische Daten

- Versorgungsspannung: 5,0 V +/- 5%

- Stromverbrauch: <= 20 mA (typ.)

- I2C-Bus Geschwindigkeit: <= 400 kHz

- GPS Antenne: eingebaut

- Backup Batterie: Lithium, im Betrieb wieder aufladbar

- Temperatur Bereich: -10 bis 65 °C

- Form Faktor: 38 x 23 mm

- Gewicht: ca. 6 g

- Empfänger Spezifikationen (UC530):

- Empfänger: GPS L1 C/A-Code, SPS

- Kanäle: 66/22 (Suche/Track)

- Tracking Empfindlichkeit: -165 dBm typ.

- Navigations Empfindlichkeit: -148 dbm typ (Kaltstart)

- Update Rate: 1 Sek.

- Positions Genauigkeit:

- 3,0m (67%) typ. horizontal

- 5,0m (67%) typ. vertikal

- 0,02 m/s (50%) typ. Geschwindigkeit

- Zeit bis zum ersten Fix: typ. 31 Sek.

- Protokoll: NMEA-0183 Rev. 3.01

Anschluss-Schema

Belegung des 9-poligen Anschluss-Steckers (K1) siehe in dieser Tabelle!

Umbau-Optionen

Wenn man den ATtiny1634 selbst programmieren will, muss man Stiftleisten auf die Platine löten.

Man braucht dazu:

- 2-reihige Stiftleiste RM 2,54mm (z.B. 2x40-polig 741306)

Man trennt von der 2-reihigen Stiftleiste 2x3 Kontakte ab und lötet sie auf die Punkte "ISP6". Mit einem ISP-Programmer kann dann eine neue Firmware geflasht werden. Die aktuelle Firmware des ATtiny1634 (Version 1.2) wird als .HEX mitgeliefert, leider ohne Source-Code.

Vorsicht: Dabei kann der Prozessor im schlimmsten Fall nicht mehr ansprechbar sein oder der GPS Empfänger UC530 beschädigt werden. Man sollte diesen Umbau und die ISP-Programmierung nur machen, wenn man genau weiß, was man macht!

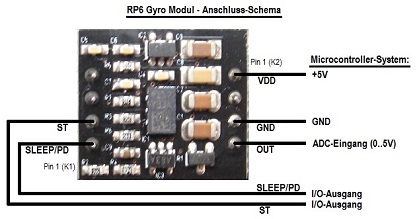

Gyro Modul JM3-GYRO

(Laut Online-Katalog der Firma CONRAD!)

"Das universelle Gyro-Sensor Modul für RP6, RP6 V2, RP6 ATMEGA32 und das RP6 V2 Control M256 Wifi-Kit ist ideal zur Erkennung der Blockierung des Roboters in seiner Drehbewegung, sowie der Stabilisierung der Geradeausfahrt."

Beschreibung

Das Gyro Modul ist eine kleine (19 x 17 mm) Zusatzplatine (RP6 Xtra Modul), die im RP6-System genutzt werden kann. Es gibt zwar keinen direkt passenden "Steckplatz" auf einer der Microcontroller-Plattformen (RP6v2, M32, M128, M256 Wifi), jedoch ist der Anschluß einfach: Benötigt werden +5V und GND, sowie ein freier ADC-Kanal, der bis 5V messen kann. Damit kann das Gyro Modul sehr universell eingesetzt werden. Es misst die Drehrate um die Z-Achse (Hochachse oder Yaw).

Die Platine ist bestückt mit dem analogen Gyro-Sensor LY330ALH, dessen Ausgangsspannung durch zwei OP-Amps (LM321, LMP7731MF) in Ruhe bei 2,5 V liegt. Höhere Ausgangsspannungen (bis 5 V) bedeuten eine Drehgeschwindigkeit nach LINKS, niedrigere (bis 0 V) eine Drehgeschwindigkeit nach RECHTS. Die 3,3 V Versorgungsspannung des LY330ALH wird auf der Platine durch einen Spannungsregler (LM3480IM3-3.3) erzeugt.

Lieferumfang

- Gyro Modul

- CD mit Anleitung und Software-Beispielen.

Technische Daten

- VDD: 5,0 V +/- 5%

- Vout(0): 2,5 V +/- 2% (ohne Bewegung)

- Vout: Vout(0) + 10mV / dps +/- 2%

- Messbereich: ca. 200 dps max.

Anschluss-Schema

Umbau-Optionen

Am Gyro Modul gibt es nichts umzubauen.

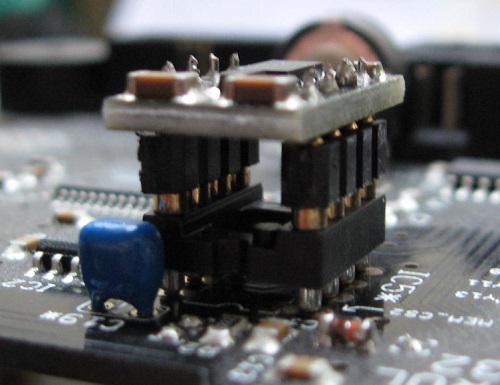

3D Accelerometer Modul JM3-3DA

(Laut Online-Katalog der Firma CONRAD!)

"Universeller 3-Achsen Beschleunigungssensor für RP6, RP6 V2, RP6 ATMEGA32 und das RP6 V2 Control M256 WIFI-Kit. Ideal zur Winkelmessung (Neigung-, Kipp-Winkel) und vieles mehr."

Beschreibung

Das 3D Accelerometer Modul ist eine kleine (15 x 10 mm) Zusatzplatine (RP6 Xtra Modul), die direkt auf den EEPROM-Sockel (IC5) der Zusatzplatine RP6 CONTROL M32 gesteckt und über den SPI-Bus angesteuert werden kann. Das Accelerometer Modul kann aber auch mit allen Microcontroller-Plattformen betrieben werden, die eine stabilisierte 5V-Versorgungsspannung und einen SPI- oder I2C-Bus bieten.

Die Platine ist bestückt mit dem 3D Beschleunigungs-Sensor LIS302DLH. Die 3,3 V Versorgungsspannung des LIS302DLH wird auf der Platine durch einen Spannungsregler (LM3480IM3-3.3) erzeugt.

Lieferumfang

- 3D Accelerometer Modul

- CD mit Anleitung und Software-Beispielen.

Technische Daten

- VDD: 5,0 V +/- 5%

- Messbereiche: +-2 g, +-4 g, +-8 g

- Datenausgabe: 16 Bit

- Schnittstellen: I2C, SPI

Anschluss-Schema

Umbau-Optionen

Will man das Modul auf der M32 einsetzen, muss man auf dem 3D Accelerometer Modul die Widerstände R2 und R3 (falls vorhanden!) auslöten (siehe Anleitung zum Modul, Seiten 4/5!) und einen IC-Sockel an Position IC5 und einen Kondensator an Position C19 auf der M32 einlöten, siehe hier!

Die Abbildung rechts zeigt das 3D Accelerometer Modul auf der M32.

Programmierung

RP6 Sensor Board

Das RP6 Sensor Board RP6-JM03-61 verfügt nicht über einen eigenen Microprozessor. Daher geht es hier eigentlich nicht um die Programmierung des Sensor Boards, sondern um die Programmierung der Microcontroller-Plattform, an die das Sensor Board angeschlossen ist. In der Regel wird das die RP6 M256 WiFi Zusatzplatine sein, aber auch die RP6v2 Base steuert in der vorgesehenen Konfiguration gewisse Funktionen des Sensor Boards an. Prinzipiell kann das Sensor Board aber auch an der RP6 CONTROL M32 oder der RP6 CCPRO M128 Zusatzplatine betrieben werden.

Dokumentation

Die Dokumentation zum RP6 Sensor Board befindet sich auf der mitgelieferten "RP6 Robot System Xtra Modules CD-ROM".

Manuals

Das Handbuch kann auch hier eingesehen werden.

ACHTUNG: Das Manual enthält aktuell noch teils irreführende Beschreibungen!

Schematics

Datasheets

Demo-Programmme

Demo-Programme zum RP6 Sensor Board befinden sich auf der mitgelieferten "RP6 Robot System Xtra Modules CD-ROM".

RP6 M256 WiFi: Sensor Board Library

Die nachfolgende RP6M256_Sensor_BoardLib (GCC) dient zur Ansteuerung des Sensor Boards durch die RP6M256 WiFi.

Configuration Header

Vor dem Kompilieren der Library muss eine Anpassung des Configuration Headers an die eigenen Hardware-Voraussetzungen erfolgen. Dazu gibt es im Configuration Header eine Definition:

- USE_PD5 -> Die Sensor Board Funktion "PD5" steuert den TCA4311A Enable Pin (EN).

Im nachfolgenden Listing ist die Definition USE_PD5 NICHT aktiv (d.h. der TCA4311A Enable Pin (EN) wird vom MAX7311 I/O 1.0 Pin angesteuert!). Dies muss an die eigene Hardware angepaßt werden. Wenn "PD5" den TCA4311A Enable Pin (EN) steuern soll, muss die Zeile mit "USE_PD5" "aktiviert" werden. Dazu entfernt man "//" am Zeilenanfang:

#define USE_PD5

Bevor man Beschleunigungs-, Magnetfeldsensor und Gyroskop nutzen kann, muss man sie kalibrieren:

- Accelerometer:

- Die X-Achse wird kalibriert, indem man den RP6 mit der rechten Seite nach unten hält und den Maximalwert in MAX_X_A einträgt. Dann neigt man ihn auf seine linke Seite und trägt den negativen Maximalwert in MIN_X_A ein.

- Die Y-Achse wird kalibriert, indem man den RP6 mit der Vorderseite nach oben hält und den Maximalwert in MAX_Y_A einträgt. Dann kippt man die Vorderseite nach unten und trägt den negativen Maximalwert in MIN_Y_A ein.

- Die Z-Achse wird kalibriert, indem man den RP6 normal waagerecht hält und den Maximalwert in MAX_Z_A einträgt. Dann dreht man den RP6 "auf den Kopf" und trägt den negativen Maximalwert in MIN_Z_A ein.

- Sollten die angezeigten Pitch- und Roll-Werte nach der Kalibrierung der Achsen und genau waagerecht stehendem Sensor bzw. RP6 vom Nullwert deutlich abweichen, kann man sie mithilfe der Definitionen OFFSET_PITCH_A und OFFSET_ROLL_A "nullen". Die Einheit dieser Definitionen ist °.

HINWEIS: Die internen Berechnungen werden durch diese Offset-Korrektur NICHT beeinflußt. Die Offset-Werte können also nicht dazu benutzt werden, eine Achsenabweichung zwischen Sensor und RP6 zu kompensieren!

- Magnetometer:

- Zur Kalibrierung des Magnetfeldsensors stellt man den RP6 auf eine waagerechte Fläche. Es dürfen keine Elektrogeräte, Metallteile und stromführende Leitungen in der Nähe sein, die das Magnetfeld verändern können.

- Zunächst ist es möglich, die sogenannten "hard iron" Effekte auszugleichen. Dies sind feste Magnetfeldabweichungen, die durch das "Gerät" (in unserem Fall also durch den kompletten RP6) verursacht werden, in oder auf dem der Sensor angebracht ist. Mit den Definitionen OFFSET_X_M, OFFSET_Y_M und OFFSET_Z_M können diese Effekte ausgeglichen werden. Diese Kalibrierung wird hier aktuell (noch) nicht beschrieben, so dass man die Werte für diese Definitionen zunächst bei 0 belassen sollte.

- Die X-Achse und Y-Achse wird kalibriert, indem man den RP6 langsam mehrfach um die eigene (Z-)Achse dreht und die Maximalwerte in MAX_X_M und MAX_Y_M einträgt. Die negativen Maximalwerte trägt man in MIN_X_M und MIN_Y_M ein.

- Die Z-Achse wird kalibriert, indem man den RP6 auf die rechte oder linke Seite legt, ihn dann langsam mehrfach auf der Stelle (um seine Y-Achse) dreht und den Maximalwert in MAX_Z_M und den negativen Maximalwert in MIN_Z_M einträgt.

- Mit der Definition DECLINATION_M kann man zur Verbesserung der Genauigkeit der Richtungsangaben den magnetischen Deklinationswert [°] (d.h. die magnetische Missweisung) am aktuellen Standort festlegen. Hier befindet sich ein "Deklinations-Rechner", mit dem man den Deklinationswert für den eigenen Standort ermitteln kann.

- Wenn man den Temperaturwert des LSM303DLHC nutzen will, muss man die Definition GET_TEMP_M aktivieren (Standard!). Den Temperaturwert kann man noch eichen, indem man die Definition OFFSET_TEMP_M anpasst. Die Einheit von OFFSET_TEMP_M ist °C.

- Gyroskop:

- In Ruhelage des RP6 wird ein ADC-Wert von ca. 511 angezeigt, wenn die Definition ADCVAL_ZERORATE_LEVEL im Configuration Header (RP6M256_Sensor_Board.h) vor der ersten Kompilierung zunächst auf 0 gesetzt wurde. Die Kalibrierung des Gyroskops ist abgeschlossen, nachdem man den in Ruhelage angezeigten ADC-Wert als ADCVAL_ZERORATE_LEVEL eingetragen hat.

HINWEISE ZUR KALIBRIERUNG:

- Das Demo-Programm ist nicht sehr gut geeignet, um die Kalibrierungen durchzuführen.

- Man sollte mit einem eigenen kurzen Kalibrierungs-Programm nur die Rohwerte der jeweiligen X-, Y- und Z-Achse z.B. zweimal pro Sekunde ausgeben.

- Die Rohwerte sind in Variablen x_axis..., y_axis..., z_axis... enthalten. Da die Rohwerte in den Funktionen normalizeLSM303DLHC_A() bzw. normalizeLSM303DLHC_M() ggf. verändert werden, müssen die Rohwerte VOR Durchlaufen dieser Funktionen ausgegeben werden.

- Ohne eine sorgfältige Kalibrierung wird die Kompass-Funktion (insbesondere die neigungskompensierte Ausgabe der Himmelsrichtung) nicht funktionieren!

- Nach dem Eintragen der Kalibrierungs-Werte in den Configuration Header (RP6M256_Sensor_Board.h) muss die Demo neu kompiliert werden. Vorher sollten die Compiler-Hilfsdateien der Sensor Board-Library (Dateiendungen .st und .o) im Programmverzeichnis gelöscht werden.

- Getestet wird das Ergebnis der Kalibrierung, indem die Ausgabewerte (Temperatur, Pitch, Roll, Heading, Neigungs-kompensiertes Heading) der Demo überprüft werden. Dazu kann man Vergleichswerte (Thermometer, Winkelmesser für Pitch, Roll und externer Kompass für Heading) heranziehen.

- Wenn die Ausgabewerte nicht den Erwartungen entsprechen, muss die Kalibrierung wiederholt werden.

- Eine Kalibrierung der Sensoren ist nur zuverlässig, solange die Position des jeweiligen Sensors und seine komplette Hardware-Umgebung (also der RP6 mit allen seinen Teilen!) nicht verändert wird. Gibt es trotzdem Veränderungen, z.B. durch weitere Aufbauten auf dem RP6, müssen diese Sensoren neu kalibriert werden.

Datei: RP6M256_Sensor_Board.h

/* * **************************************************************************** * RP6 ROBOT SYSTEM - RP6 CONTROL M256 Examples * **************************************************************************** * Example: RP6M256 Sensor Board Library * Author(s): Dirk * **************************************************************************** * Description: * Configuration header file for new RP6 Sensor Board library. * The RP6 Sensor Board (CONRAD 1082384) is connected to the RP6M256 with the * two plugs: * Sensor Board <---> RP6M256 * -------------------------------- * I/O (K17) <---> IO_PWM/T0/T1 * ADC (K18) <---> ADC_IO2/CMP * The RP6 Sensor Board function "PD5" (IC6: EN) is now connected to RP6M256 * OC1B (PB6) and the RP6 Sensor Board function "ADC4" (SHARP_R) to RP6M256 * ADC9 (PK1). * On the RP6 Sensor Board the functions "ADC0", "ADC1", "PWR" and "ADC4" are * connected to the USRBUS. The USRBUS may be wired on the RP6 mainboard like * this: * Function : Sensor Board - USRBUS: * <---> RP6 Mainboard * -------------------------------------------------------- * SHARP_F : "ADC0" - Pin 1 <---> ADC0: Pin 3 * GYRO : "ADC1" - Pin 2 <---> ADC1: Pin 3 * PWRON ² : "PWR" - Pin 3 <---> PWR * SHARP_R : "ADC4" - Pin 5 <---> Not connected! * At *) It is also possible not to use the USRBUS, but to connect the RP6 * Sensor Board directly to the RP6 mainboard with 3 single cables. * At ²) See RP6 manual "4.6.8. Stromsparfunktionen"! * * **************************************************************************** */ #ifndef RP6M256_SENSOR_BOARD_H #define RP6M256_SENSOR_BOARD_H /*****************************************************************************/ // RP6 Sensor Board hardwired components: // - I2C I/O Port Expander (MAX7311) // - I2C Real Time Clock (RTC DS1339) // - I2C Temperature Sensor (LM75B) // - I2C Servo Controller (PCA9685) // - I2C LED Driver (TCA6507) // - I2C 3D Magnetometer & Accelerometer (LSM303DLHC) // - Analog Yaw-Rate Gyroscope (LY330ALH) // - Hot Swappable 2-Wire Bus Buffer (TCA4311A) // - Button // - Status LED /*****************************************************************************/ // I2C I/O Port Expander (MAX7311): #define I2C_SENSOR_PORTEXP_ADR 0x40 // Default // Interrupt I/O portpin definitions (RP6M256): #define IO_SENSOR_INT1_IN INT1_PI12 // PCINT12 PJ3 XBUS Pin 8 #define IO_SENSOR_INT1_DDR DDRJ #define IO_SENSOR_INT1_PIN PINJ #define IO_SENSOR_INT1_PORT PORTJ #define IO_SENSOR_INT2_IN INT2_PI15 // PCINT15 PJ6 XBUS Pin 11 #define IO_SENSOR_INT2_DDR DDRJ #define IO_SENSOR_INT2_PIN PINJ #define IO_SENSOR_INT2_PORT PORTJ #define IO_SENSOR_INT3_IN INT3_PI14 // PCINT14 PJ5 XBUS Pin 9 #define IO_SENSOR_INT3_DDR DDRJ #define IO_SENSOR_INT3_PIN PINJ #define IO_SENSOR_INT3_PORT PORTJ #define IO_SENSOR_INTU_IN INTU_PI13 // PCINT13 PJ4 XBUS Pin 7 #define IO_SENSOR_INTU_DDR DDRJ #define IO_SENSOR_INTU_PIN PINJ #define IO_SENSOR_INTU_PORT PORTJ // I/O PORT pin numbers: #define PIN7 7 #define PIN6 6 #define PIN5 5 #define PIN4 4 #define PIN3 3 #define PIN2 2 #define PIN1 1 #define PIN0 0 /*****************************************************************************/ // I2C Real Time Clock (RTC DS1339): #define I2C_SENSOR_RTC_ADR 0xD0 // Default /*****************************************************************************/ // I2C Temperature Sensor (LM75B): #define I2C_SENSOR_TEMP_ADR 0x90 // Default /*****************************************************************************/ // I2C Servo Controller (PCA9685): #define I2C_SENSOR_SERVO_ADR 0x88 // Default // Servo and PWM channels: #define CH_SERVO_1 16 // At K6: 1 "SERVO_1" #define CH_SERVO_2 15 // At K11: 1 "SERVO_2" #define CH_SERVO_3 13 // At K29: 1 "SERVO_3" #define CH_SERVO_4 14 // At K30: 1 "SERVO_4" #define CH_SERVO_5 11 // At K31: 1 "SERVO_5" #define CH_SERVO_6 12 // At K32: 1 "SERVO_6" #define CH_SERVO_7 9 // At K33: 1 "SERVO_7" #define CH_SERVO_8 10 // At K34: 1 "SERVO_8" #define CH_PWM_OUT_1 1 // At K12: 1 "PWM_OUT" #define CH_PWM_OUT_2 2 // At K12: 2 #define CH_PWM_OUT_3 3 // At K12: 3 #define CH_PWM_OUT_4 4 // At K12: 4 #define CH_PWM_OUT_5 5 // At K12: 5 #define CH_PWM_OUT_6 6 // At K12: 6 #define CH_PWM_OUT_7 7 // At K12: 7 #define CH_PWM_OUT_8 8 // At K12: 8 // Servo left touch (LT), right touch (RT), middle position (MP) constants: // (Hints: - Servo impulse length [ms] = Servo position value / 204.8 // (Formula only valid for a PWM of 50 Hz!) // - Min. servo impulse (0,7 ms) = Servo position 143 // - Mid. servo impulse (1,5 ms) = Servo position 307 // - Max. servo impulse (2,3 ms) = Servo position 471 // - !!! You should NOT use servo position values < 143 or > 471 !!!) #define SERVO1_LT 205 // Servo impulse ~1ms #define SERVO1_RT 410 // Servo impulse ~2ms #define SERVO1_MP ((SERVO1_RT - SERVO1_LT) / 2 + SERVO1_LT) #define SERVO2_LT 205 #define SERVO2_RT 410 #define SERVO2_MP ((SERVO2_RT - SERVO2_LT) / 2 + SERVO2_LT) #define SERVO3_LT 205 #define SERVO3_RT 410 #define SERVO3_MP ((SERVO3_RT - SERVO3_LT) / 2 + SERVO3_LT) #define SERVO4_LT 205 #define SERVO4_RT 410 #define SERVO4_MP ((SERVO4_RT - SERVO4_LT) / 2 + SERVO4_LT) #define SERVO5_LT 205 #define SERVO5_RT 410 #define SERVO5_MP ((SERVO5_RT - SERVO5_LT) / 2 + SERVO5_LT) #define SERVO6_LT 205 #define SERVO6_RT 410 #define SERVO6_MP ((SERVO6_RT - SERVO6_LT) / 2 + SERVO6_LT) #define SERVO7_LT 205 #define SERVO7_RT 410 #define SERVO7_MP ((SERVO7_RT - SERVO7_LT) / 2 + SERVO7_LT) #define SERVO8_LT 205 #define SERVO8_RT 410 #define SERVO8_MP ((SERVO8_RT - SERVO8_LT) / 2 + SERVO8_LT) /*****************************************************************************/ // I2C LED Driver (TCA6507): #define I2C_SENSOR_LEDDRIVER_ADR 0x8A // Default // LED numbers: #define LED0 0 // At K7 #define DISPLAY_BACKLIGHT 0 // Display background light #define LED1 1 // At K4 #define LED2 2 // At K2 #define LED3 3 // At K10: 1 #define BACKLIGHT_R 3 // Right backlight #define LED4 4 // At K10: 2 #define BACKLIGHT_L 4 // Left backlight #define LED5 5 // White LED (D3) #define HEADLIGHT_R 5 // Right headlight #define LED6 6 // White LED (D1) #define HEADLIGHT_L 6 // Left headlight /*****************************************************************************/ // I2C 3D Magnetometer & Accelerometer (LSM303DLHC): // LSM303DLHC accelerometer: #define I2C_SENSOR_LSM303DLHC_A_ADR 0x32 // Default // LSM303DLHC accelerometer calibration data: #define MAX_X_A 1037 // Max. X-axis value #define MIN_X_A -1030 // Min. X-axis value #define MAX_Y_A 1030 // Max. Y-axis value #define MIN_Y_A -1019 // Min. Y-axis value #define MAX_Z_A 1062 // Max. Z-axis value #define MIN_Z_A -1056 // Min. Z-axis value #define OFFSET_PITCH_A 0.0 // Offset Pitch [°] #define OFFSET_ROLL_A 0.0 // Offset Roll [°] // LSM303DLHC magnetometer: #define I2C_SENSOR_LSM303DLHC_M_ADR 0x3c // Default // LSM303DLHC magnetometer calibration data: #define MAX_X_M -111.0 // Max. X-axis value #define MIN_X_M -634.0 // Min. X-axis value #define OFFSET_X_M 0 // Hard iron X-axis offset #define MAX_Y_M 297.0 // Max. Y-axis value #define MIN_Y_M -215.0 // Min. Y-axis value #define OFFSET_Y_M 0 // Hard iron Y-axis offset #define MAX_Z_M 183.0 // Max. Z-axis value #define MIN_Z_M -214.0 // Min. Z-axis value #define OFFSET_Z_M 0 // Hard iron Z-axis offset #define DECLINATION_M 0.0 // E at local position [°] // LSM303DLHC temperature sensor definitions: #define GET_TEMP_M // Enable temperature sensor #define OFFSET_TEMP_M 0.0 // Temperature offset [°C] /*****************************************************************************/ // Analog Yaw-Rate Gyroscope (LY330ALH): // LY330ALH gyroscope: #define ADC_SENSOR_LY330ALH ADC_1 // At USRBUS: 2 (RP6BASE) // LY330ALH gyroscope calibration data: // (Higher values [505..1023] mean an angular velocity while rotating LEFT // and lower values [503..0] while rotating RIGHT!) #define ADCVAL_MINRATE 0 // Min. rate value #define ADCVAL_ZERORATE_LEVEL 504 // Zero rate level #define ADCVAL_MAXRATE 1023 // Max. rate value /*****************************************************************************/ // Hot Swappable 2-Wire Bus Buffer (TCA4311A): // Define USE_PD5, if you want to control the TCA4311A enable pin (EN) with // the RP6 Sensor Board function "PD5". If USE_PD5 is NOT defined (default), // the TCA4311A EN pin is controlled by the MAX7311 I/O 1.0 pin. // --------------- //#define USE_PD5 // --------------- #define IO_SENSOR_TCA4311A_EN_IN OC1B_PI6 // At I/O: 9 (RP6M256) #define IO_SENSOR_TCA4311A_EN_DDR DDRB #define IO_SENSOR_TCA4311A_EN_PIN PINB #define IO_SENSOR_TCA4311A_EN_PORT PORTB /*****************************************************************************/ // Button: // (Button is connected to I/O 1.7 of the MAX7311!) /*****************************************************************************/ // Status LED: // (Status LED is connected to I/O 1.6 of the MAX7311!) /*****************************************************************************/ // Other ADC channel definitions: // (Depending on connections on the RP6 Sensor Board!) #define ADC_SENSOR_SHARP_F ADC_0 // At USRBUS: 1 (RP6BASE) #define ADC_SENSOR_SHARP_R ADC_9 // At ADC: 3 (RP6M256) /*****************************************************************************/ #endif /****************************************************************************** * Additional info * **************************************************************************** * Changelog: * * ---> changes are documented in the file "RP6M256_Sensor_BoardLib.c" * * **************************************************************************** */ /*****************************************************************************/ // EOF

Library Header

Datei: RP6M256_Sensor_BoardLib.h

/*

* ****************************************************************************

* RP6 ROBOT SYSTEM - RP6 CONTROL M256 Examples

* ****************************************************************************

* Example: RP6M256 Sensor Board Library

* Author(s): Dirk

* ****************************************************************************

* Description:

* Header file for new RP6 Sensor Board library.

*

* ****************************************************************************

*/

#ifndef RP6M256_SENSOR_BOARDLIB_H

#define RP6M256_SENSOR_BOARDLIB_H

/*****************************************************************************/

// RP6 Sensor Board hardwired components:

// - I2C I/O Port Expander (MAX7311)

// - I2C Real Time Clock (RTC DS1339)

// - I2C Temperature Sensor (LM75B)

// - I2C Servo Controller (PCA9685)

// - I2C LED Driver (TCA6507)

// - I2C 3D Magnetometer & Accelerometer (LSM303DLHC)

// - Analog Yaw-Rate Gyroscope (LY330ALH)

// - Hot Swappable 2-Wire Bus Buffer (TCA4311A)

// - Button

// - Status LED

/*****************************************************************************/

// Includes:

#include "RP6M256Lib.h"

#include "RP6I2CmasterTWI.h"

#include "RP6M256_Sensor_Board.h"

#include <math.h>

/*****************************************************************************/

// RP6M256_I2CMasterLib definitions:

#ifndef I2C_RP6_BASE_ADR

#define I2C_RP6_BASE_ADR 10

#endif

#ifndef I2C_REG_ADC_ADC0_L

#define I2C_REG_ADC_ADC0_L 23

#endif

#ifndef I2C_REG_ADC_ADC1_L

#define I2C_REG_ADC_ADC1_L 25

#endif

#ifndef CMD_POWER_OFF

#define CMD_POWER_OFF 0

#endif

#ifndef CMD_POWER_ON

#define CMD_POWER_ON 1

#endif

/*****************************************************************************/

// I2C I/O Port Expander (MAX7311):

// Registers:

#define MAX7311_INPUT_PORT1 0

#define MAX7311_INPUT_PORT2 1

#define MAX7311_OUTPUT_PORT1 2

#define MAX7311_OUTPUT_PORT2 3

#define MAX7311_PORT1_POL_INV 4

#define MAX7311_PORT2_POL_INV 5

#define MAX7311_PORT1_CONFIG 6

#define MAX7311_PORT2_CONFIG 7

#define MAX7311_TIMEOUT 8

// Port 1 configuration register bitmasks:

#define ST_GYRO (1 << PIN7) // I/O 0.7 (Output)

#define PD_GYRO (1 << PIN6) // I/O 0.6 (Output)

#define PWR_CAM_IF (1 << PIN5) // I/O 0.5 (Output)

#define EN_LEDDRIV (1 << PIN4) // I/O 0.4 (Output)

#define RDY_BUSBUFF (1 << PIN3) // I/O 0.3 (Input)

#define PWR_SHARP_R (1 << PIN2) // I/O 0.2 (Output)

#define PWR_SHARP_F (1 << PIN1) // I/O 0.1 (Output)

#define PWR_I2C (1 << PIN0) // I/O 0.0 (Output)

// Port 2 configuration register bitmasks:

#define IO2_I2C (1 << PIN7) // I/O 1.7 (Input)

#define IO1_I2C (1 << PIN6) // I/O 1.6 (Output)

#define DRDY_MAGACC (1 << PIN5) // I/O 1.5 (Input)

#define PWR_SERVO (1 << PIN4) // I/O 1.4 (Output)

#define OEN_SERVO (1 << PIN3) // I/O 1.3 (Output)

#define IO_K19_1 (1 << PIN2) // I/O 1.2 (Input)

#define IO_K19_3 (1 << PIN1) // I/O 1.1 (Input)

#define EN_BUSBUFF (1 << PIN0) // I/O 1.0 (Output)

// Port 1 & 2 register 16-bit bitmasks:

// (CONFIG: 1 = Input, 0 = Output)

#define MAX7311_CONFIG_DEFAULT 0b1010011000001000

#define MAX7311_CONFIG_USE_PD5 0b1010011100001000

// (OUTPUT: 1 = High/True, 0 = Low/False)

#define MAX7311_OUTPUT_DEFAULT 0b0100000100010000

#define MAX7311_OUTPUT_FULLPOWER 0b0001000100110111

#define MAX7311_OUTPUT_SHUTDOWN 0b0100100011000000

// Safe configuration:

// (Ensures if activated, that I/Os 0.3, 1.5 and 1.7 cannot be configured

// as output with the function MAX7311_write_cfg(). This may protect the

// RP6 Sensor Board from hardware damage.)

// -------------------

#define SAFE_CONFIG

// -------------------

typedef union {

uint8_t byte;

struct {

unsigned int1 :1; // INT1 XBUS Pin 8

unsigned int2 :1; // INT2 XBUS Pin 11

unsigned int3 :1; // INT3 XBUS Pin 9

unsigned intu :1; // INTU XBUS Pin 7

unsigned unused :4;

};

struct {

unsigned magacc1 :1; // INT1: LSM303DLHC INT1

unsigned portexp :1; // INT2: MAX7311 INT_N

unsigned magacc2_rtc :1; // INT3: LSM303DLHC INT2

unsigned noname :5; // OR DS1339 SQW/INT_N

};

} interrupt_RP6SBstatus_t;

extern interrupt_RP6SBstatus_t interrupt_RP6SBstatus;

typedef union {

uint16_t word;

struct {

unsigned pwr_i2c :1; // I/O 0.0 (Output)

unsigned pwr_sharp_f :1; // I/O 0.1 (Output)

unsigned pwr_sharp_r :1; // I/O 0.2 (Output)

unsigned rdy_busbuff :1; // I/O 0.3 (Input)

unsigned en_leddriv :1; // I/O 0.4 (Output)

unsigned pwr_cam_if :1; // I/O 0.5 (Output)

unsigned pd_gyro :1; // I/O 0.6 (Output)

unsigned st_gyro :1; // I/O 0.7 (Output)

unsigned en_busbuff :1; // I/O 1.0 (Output)

unsigned io_k19_3 :1; // I/O 1.1 (Input)

unsigned io_k19_1 :1; // I/O 1.2 (Input)

unsigned oen_servo :1; // I/O 1.3 (Output)

unsigned pwr_servo :1; // I/O 1.4 (Output)

unsigned drdy_magacc :1; // I/O 1.5 (Input)

unsigned io1_i2c :1; // I/O 1.6 (Output)

unsigned io2_i2c :1; // I/O 1.7 (Input)

};

} max7311IOs_t;

extern max7311IOs_t inport;

extern max7311IOs_t outport;

extern uint8_t readyBusbuff;

extern uint8_t pressedButton;

void MAX7311_write_cfg(uint16_t);

void task_checkINTs(void);

void task_RP6SensorBoard(void);

void MAX7311_update(void);

void MAX7311_write(uint16_t);

void MAX7311_init(void);

/*****************************************************************************/

// I2C Real Time Clock (RTC DS1339):

// Registers:

#define DS1339_SECONDS 0

#define DS1339_MINUTES 1

#define DS1339_HOURS 2

#define DS1339_DAY 3

#define DS1339_DATE 4

#define DS1339_MONTH_CENTURY 5

#define DS1339_YEAR 6

#define DS1339_ALARM1_SECONDS 7

#define DS1339_ALARM1_MINUTES 8

#define DS1339_ALARM1_HOURS 9

#define DS1339_ALARM1_DAY_DATE 10

#define DS1339_ALARM2_MINUTES 11

#define DS1339_ALARM2_HOURS 12

#define DS1339_ALARM2_DAY_DATE 13

#define DS1339_CONTROL 14

#define DS1339_STATUS 15

#define DS1339_TRICKLE_CHARGER 16

// Control register bitmasks:

#define DS1339_CONTROL_DEFAULT 0 // Power on default

#define DS1339_CONTROL_A1IE 1

#define DS1339_CONTROL_A2IE 2

#define DS1339_CONTROL_INTCN 4

#define DS1339_CONTROL_RS1 8

#define DS1339_CONTROL_RS2 16

#define DS1339_CONTROL_BBSQI 32

#define DS1339_CONTROL_EOSC 128

// Trickle Charger register bitmasks:

#define DS1339_TRICKLE_CHARGER_DEFAULT 0b10101010 // One diode, 2k resistor

#define DS1339_TRICKLE_CHARGER_ROUT0 1

#define DS1339_TRICKLE_CHARGER_ROUT1 2

#define DS1339_TRICKLE_CHARGER_DS0 4

#define DS1339_TRICKLE_CHARGER_DS1 8

#define DS1339_TRICKLE_CHARGER_TCS0 16

#define DS1339_TRICKLE_CHARGER_TCS1 32

#define DS1339_TRICKLE_CHARGER_TCS2 64

#define DS1339_TRICKLE_CHARGER_TCS3 128

enum RTCWEEKDAYS {

R_MO = 1, R_TU, R_WE, R_TH, R_FR, R_SA, R_SU

};

typedef struct {

uint16_t year; // Year

uint8_t month; // Month [1..12]

enum RTCWEEKDAYS weekday; // Weekday [1..7 = R_MO..R_SU]

uint8_t day; // Day [1..31]

} rtcdate_t;

rtcdate_t rtc_date;

typedef struct {

uint8_t dst; // Daylight-saving-time (time zone)

uint8_t hour; // Hour [0..23]

uint8_t minute; // Minute [0..59]

uint8_t second; // Second [0..59]

} rtctime_t;

rtctime_t rtc_time;

uint8_t BCD2DEC(uint8_t);

uint8_t DEC2BCD(uint8_t);

void DS1339_write_cfg(uint8_t);

void DS1339_init(void);

#define CALC_DST // Time zone will be calculated

void DS1339_read(void);

void DS1339_write(void);

/*****************************************************************************/

// I2C Temperature Sensor (LM75B):

// Registers:

#define LM75B_TEMP 0

#define LM75B_CONF 1

#define LM75B_THYST 2

#define LM75B_TOS 3

// Conf register bitmasks:

#define LM75B_CONF_DEFAULT 0 // Power on default

#define LM75B_CONF_SHUTDOWN 1

#define LM75B_CONF_OS_COMP_INT 2

#define LM75B_CONF_OS_POL 4

#define LM75B_CONF_OS_F_QUE0 8

#define LM75B_CONF_OS_F_QUE1 16

extern double temperature;

void LM75B_write_cfg(uint8_t);

#define LM75B_shutdown() {LM75B_write_cfg(LM75B_CONF_SHUTDOWN);}

#define LM75B_init() {LM75B_write_cfg(LM75B_CONF_DEFAULT);}

extern uint8_t temperature_low;

extern uint8_t temperature_high;

#define getTemperatureHigh() (temperature_high)

#define getTemperatureLow() (temperature_low)

void LM75B_read(void);

double LM75B_calculate(void);

double LM75B_measure(void);

/*****************************************************************************/

// I2C Servo Controller (PCA9685):

// Registers:

#define PCA9685_MODE1 0

#define PCA9685_MODE2 1

#define PCA9685_SUBADR1 2

#define PCA9685_SUBADR2 3

#define PCA9685_SUBADR3 4

#define PCA9685_ALLCALLADR 5

#define PCA9685_LED0_ON_L 6

#define PCA9685_LED0_ON_H 7

#define PCA9685_LED0_OFF_L 8

#define PCA9685_LED0_OFF_H 9

#define PCA9685_LED1_ON_L 10

#define PCA9685_LED1_ON_H 11

#define PCA9685_LED1_OFF_L 12

#define PCA9685_LED1_OFF_H 13

#define PCA9685_LED2_ON_L 14

#define PCA9685_LED2_ON_H 15

#define PCA9685_LED2_OFF_L 16

#define PCA9685_LED2_OFF_H 17

#define PCA9685_LED3_ON_L 18

#define PCA9685_LED3_ON_H 19

#define PCA9685_LED3_OFF_L 20

#define PCA9685_LED3_OFF_H 21

#define PCA9685_LED4_ON_L 22

#define PCA9685_LED4_ON_H 23

#define PCA9685_LED4_OFF_L 24

#define PCA9685_LED4_OFF_H 25

#define PCA9685_LED5_ON_L 26

#define PCA9685_LED5_ON_H 27

#define PCA9685_LED5_OFF_L 28

#define PCA9685_LED5_OFF_H 29

#define PCA9685_LED6_ON_L 30

#define PCA9685_LED6_ON_H 31

#define PCA9685_LED6_OFF_L 32

#define PCA9685_LED6_OFF_H 33

#define PCA9685_LED7_ON_L 34

#define PCA9685_LED7_ON_H 35

#define PCA9685_LED7_OFF_L 36

#define PCA9685_LED7_OFF_H 37

#define PCA9685_LED8_ON_L 38

#define PCA9685_LED8_ON_H 39

#define PCA9685_LED8_OFF_L 40

#define PCA9685_LED8_OFF_H 41

#define PCA9685_LED9_ON_L 42

#define PCA9685_LED9_ON_H 43

#define PCA9685_LED9_OFF_L 44

#define PCA9685_LED9_OFF_H 45

#define PCA9685_LED10_ON_L 46

#define PCA9685_LED10_ON_H 47

#define PCA9685_LED10_OFF_L 48

#define PCA9685_LED10_OFF_H 49

#define PCA9685_LED11_ON_L 50

#define PCA9685_LED11_ON_H 51

#define PCA9685_LED11_OFF_L 52

#define PCA9685_LED11_OFF_H 53

#define PCA9685_LED12_ON_L 54

#define PCA9685_LED12_ON_H 55

#define PCA9685_LED12_OFF_L 56

#define PCA9685_LED12_OFF_H 57

#define PCA9685_LED13_ON_L 58

#define PCA9685_LED13_ON_H 59

#define PCA9685_LED13_OFF_L 60

#define PCA9685_LED13_OFF_H 61

#define PCA9685_LED14_ON_L 62

#define PCA9685_LED14_ON_H 63

#define PCA9685_LED14_OFF_L 64

#define PCA9685_LED14_OFF_H 65

#define PCA9685_LED15_ON_L 66

#define PCA9685_LED15_ON_H 67

#define PCA9685_LED15_OFF_L 68

#define PCA9685_LED15_OFF_H 69

#define PCA9685_ALL_LED_ON_L 250

#define PCA9685_ALL_LED_ON_H 251

#define PCA9685_ALL_LED_OFF_L 252

#define PCA9685_ALL_LED_OFF_H 253

#define PCA9685_PRE_SCALE 254

#define PCA9685_TESTMODE 255

// Mode1 register bitmasks:

#define PCA9685_MODE1_ALLCALL 1

#define PCA9685_MODE1_SUB3 2

#define PCA9685_MODE1_SUB2 4

#define PCA9685_MODE1_SUB1 8

#define PCA9685_MODE1_SLEEP 16

#define PCA9685_MODE1_AI 32

#define PCA9685_MODE1_EXTCLK 64

#define PCA9685_MODE1_RESTART 128

// Mode2 register bitmasks:

#define PCA9685_MODE2_OUTNE01_DEFAULT 0

#define PCA9685_MODE2_OUTDRV 4

#define PCA9685_MODE2_OCH 8

#define PCA9685_MODE2_INVRT 16

#define F_PCA9685 25000000.0 // Int. Clock: 25 MHz

void PCA9685_init(uint16_t);

#define initServo(__FREQ__) {PCA9685_init(__FREQ__);}

uint8_t servo(uint8_t);

void PCA9685_set(uint8_t, uint16_t);

#define setServo(__SERVO__,__POS__) {PCA9685_set(servo(__SERVO__),__POS__);}

void PCA9685_shutdown(void);

void PCA9685_restart(void);

void setServoPower(uint8_t);

/*****************************************************************************/

// I2C LED Driver (TCA6507):

// Registers:

#define TCA6507_SELECT0 0

#define TCA6507_SELECT1 1

#define TCA6507_SELECT2 2

#define TCA6507_FADEON_TIME 3

#define TCA6507_FULLYON_TIME 4

#define TCA6507_FADEOFF_TIME 5

#define TCA6507_1ST_FULLYOFF_TIME 6

#define TCA6507_2ND_FULLYOFF_TIME 7

#define TCA6507_MAXIMUM_INTENSITY 8

#define TCA6507_MASTER_INTENSITY 9

#define TCA6507_INITIALIZATION 10

// Output states:

#define STATE_OFF 0

#define STATE_PWM0 2

#define STATE_PWM1 3

#define STATE_ON 4

#define STATE_MINT 5

#define STATE_BLINK0 6

#define STATE_BLINK1 7

extern uint8_t select[3];

void TCA6507_write_cfg(uint8_t, uint8_t);

void TCA6507_update(void);

void TCA6507_set(uint8_t, uint8_t);

#define setLED(__LED__,__STATE__) {TCA6507_set(__LED__,__STATE__);}

void TCA6507_shutdown(void);

void TCA6507_restart(void);

void TCA6507_init(void);

/*****************************************************************************/

// I2C 3D Magnetometer & Accelerometer (LSM303DLHC):

// LSM303DLHC accelerometer internal registers:

#define CTRL_REG1_A 0x20

#define CTRL_REG2_A 0x21

#define CTRL_REG3_A 0x22

#define CTRL_REG4_A 0x23

#define CTRL_REG5_A 0x24

#define CTRL_REG6_A 0x25

#define REFERENCE_A 0x26

#define STATUS_REG_A 0x27

#define OUT_X_L_A 0x28

#define OUT_X_H_A 0x29

#define OUT_Y_L_A 0x2a

#define OUT_Y_H_A 0x2b

#define OUT_Z_L_A 0x2c

#define OUT_Z_H_A 0x2d

#define FIFO_CTRL_REG_A 0x2e

#define FIFO_SRC_REG_A 0x2f

#define INT1_CFG_A 0x30

#define INT1_SOURCE_A 0x31

#define INT1_THS_A 0x32

#define INT1_DURATION_A 0x33

#define INT2_CFG_A 0x34

#define INT2_SOURCE_A 0x35

#define INT2_THS_A 0x36

#define INT2_DURATION_A 0x37

#define CLICK_CFG_A 0x38

#define CLICK_SRC_A 0x39

#define CLICK_THS_A 0x3a

#define TIME_LIMIT_A 0x3b

#define TIME_LATENCY_A 0x3c

#define TIME_WINDOW_A 0x3d

// LSM303DLHC accelerometer register settings:

#define CTRL_REG1_A_10HZ 0b00100111 // 10Hz & all axes enable

#define CTRL_REG1_A_50HZ 0b01000111 // 50Hz & all axes enable

#define CTRL_REG4_A_DEFAULT 0b00000000 // Default (Normal mode)

#define CTRL_REG4_A_HR 0b00001000 // HR output mode

// LSM303DLHC magnetometer internal registers:

#define CRA_REG_M 0x00

#define CRB_REG_M 0x01

#define MR_REG_M 0x02

#define OUT_X_H_M 0x03

#define OUT_X_L_M 0x04

#define OUT_Z_H_M 0x05

#define OUT_Z_L_M 0x06

#define OUT_Y_H_M 0x07

#define OUT_Y_L_M 0x08

#define SR_REG_MG 0x09

#define IRA_REG_M 0x0a

#define IRB_REG_M 0x0b

#define IRC_REG_M 0x0c

#define TEMP_OUT_H_M 0x31

#define TEMP_OUT_L_M 0x32

// LSM303DLHC magnetometer register settings:

#define CRA_REG_M_15HZ 0b00010000 // Default (Data rate 15Hz)

#define CRA_REG_M_15HZ_T_EN 0b10010000 // 15Hz & temperature enable

#define CRB_REG_M_13GAUSS 0b00100000 // Gain +-1.3Gauss

#define MR_REG_M_CCM 0b00000000 // Continuous-conversion mode

#define MR_REG_M_SCM 0b00000001 // Single-conversion mode

#define MR_REG_M_SLEEP 0b00000011 // Default (Sleep-mode)

extern int16_t x_axisa, y_axisa, z_axisa;

extern double pitch, roll;

extern double xa, ya, za;

extern double the, phi;

extern int16_t x_axism, y_axism, z_axism;

extern int16_t headingm;

extern double xm, ym, zm;

#ifdef GET_TEMP_M

extern int16_t temperaturem;

extern double temperature_mag;

#endif

extern int16_t headingtc;

void LSM303DLHC_A_init(void);

void readLSM303DLHC_A(void);

void normalizeLSM303DLHC_A(void);

void positionLSM303DLHC_A(void);

void LSM303DLHC_M_init(void);

void readLSM303DLHC_M(void);

void normalizeLSM303DLHC_M(void);

int16_t headingLSM303DLHC_M(void);

int16_t headingLSM303DLHC_TC(void);

void LSM303DLHC_init(void);

/*****************************************************************************/

// Analog Yaw-Rate Gyroscope (LY330ALH):

#define LY330ALH_MODE_NORMAL 0 // Power on default

#define LY330ALH_MODE_SLEEP 1

#define LY330ALH_MODE_SELFTEST 2

#define LY330ALH_MODE_POWERDOWN 3 // Shutdown mode

extern int16_t z_axisg;

void LY330ALH_set_mode(uint8_t);

uint16_t getRP6Base_ADC1(void);

int16_t LY330ALH_measure(void);

/*****************************************************************************/

// Hot Swappable 2-Wire Bus Buffer (TCA4311A):

//extern uint8_t readyBusbuff; // See "I2C I/O Port Expander" section

extern uint8_t errorBusbuff;

#define getReadyBusbuff() (readyBusbuff)

uint8_t readReadyBusbuff(void);

void TCA4311A_shutdown(void);

void TCA4311A_reconnect(void);

void setRP6Base_PWR(uint8_t);

void setI2CModulePower(uint8_t);

/*****************************************************************************/

// Button:

//extern uint8_t pressedButton; // See "I2C I/O Port Expander" section

#define getPressedButton() (pressedButton)

uint8_t readButton(void);

/*****************************************************************************/

// Status LED:

void setStatusLED(uint8_t);

/*****************************************************************************/

// RP6 Sensor Board initialisation and shutdown:

void sensor_board_init(void);

void sensor_board_shutdown(void);

/*****************************************************************************/

#endif

/******************************************************************************

* Additional info

* ****************************************************************************

* Changelog:

*

* ---> changes are documented in the file "RP6M256_Sensor_BoardLib.c"

*

* ****************************************************************************

*/

/*****************************************************************************/

// EOF

Library Source

Datei: RP6M256_Sensor_BoardLib.c

/*

* ****************************************************************************

* RP6 ROBOT SYSTEM - RP6 CONTROL M256 Examples

* ****************************************************************************

* Example: RP6M256 Sensor Board Library

* Author(s): Dirk

* ****************************************************************************

* Description:

* This is our new Library that contains basic routines and functions for

* accessing the hardwired components of the RP6 Sensor Board (CONRAD 1082384).

* This library assumes the RP6 Sensor Board Revision 2.0 (04.07.13).

*

* There are more sensors and actors, that may be connected to the RP6 Sensor

* Board: Many I2C components including a GPS module (CONRAD 1082385), servo

* motors, SHARP IR distance sensors, LEDs, a camera ...

* This library doesn't contain functions for these sensors/actors, because

* they are not HARDWIRED to the RP6 Sensor Board and may be connected

* OPTIONALLY.

*

* ****************************************************************************

*/

/*****************************************************************************/

// RP6 Sensor Board hardwired components:

// - I2C I/O Port Expander (MAX7311)

// - I2C Real Time Clock (RTC DS1339)

// - I2C Temperature Sensor (LM75B)

// - I2C Servo Controller (PCA9685)

// - I2C LED Driver (TCA6507)

// - I2C 3D Magnetometer & Accelerometer (LSM303DLHC)

// - Analog Yaw-Rate Gyroscope (LY330ALH)

// - Hot Swappable 2-Wire Bus Buffer (TCA4311A)

// - Button

// - Status LED

/*****************************************************************************/

// Includes:

#include "RP6M256_Sensor_BoardLib.h"

/*****************************************************************************/

// Variables:

uint8_t registerBuf[13];

/*****************************************************************************/

// I2C I/O Port Expander (MAX7311):

/**

* Sends the configuration word to a MAX7311.

*

* Input: config -> Config word for control

* registers

*

*/

void MAX7311_write_cfg(uint16_t config)

{

#ifdef SAFE_CONFIG

config |= 0b1010000000001000;

#endif

I2CTWI_transmit3Bytes(I2C_SENSOR_PORTEXP_ADR, MAX7311_PORT1_CONFIG, config, (config>>8));

}

interrupt_RP6SBstatus_t interrupt_RP6SBstatus;

/**

* This function checks all interrupt pins on

* the XBUS (INT1..3, INTU).

* This function must be called VERY frequently

* out of the main loop.

* Bigger delays result in slower reaction to

* interrupt requests of the RP6 Sensor Board.

* Interrupt function table:

* Int. : Function 1 IRQ Function 2 IRQ

* -------------------------------------------------

* INT1 : LSM303DLHC INT1 H

* INT2 : MAX7311 INT_N L

* INT3 : LSM303DLHC INT2 H DS1339 SQW/INT_N L

* INTU : not used

* You can see in the "IRQ" column, which level

* (H/L) means an ACTIVE INTERRUPT signal.

* The interrupt pin levels (H=true/L=false) are

* read into the global interrupt_RP6SBstatus

* variable.

*

* Hints: - This function checks the interrupt

* signals by polling. This is NOT the

* best way to to this job. You will

* have to write your own task, if you

* want to use the Pin Change Interrupt

* function of the ATmega2560

* microcontroller.

* - You cannot use both interrupt sources

* for INT3! So you should not use INT2

* of the LSM303DLHC together with the

* alarm function of the DS1339 (RTC)!

* - Every interrupt signal of the Sensor

* Board may be cut off from the XBUS

* by opening a jumper (Jx):

* INT1 -> J3 (LSM303DLHC INT1)

* INT2 -> J4 (MAX7311 INT_N)

* INT3 -> J2 (DS1339 SQW/INT_N)

* INT3 -> J5 (LSM303DLHC INT2)

*

* Example:

*

* if (!interrupt_RP6SBstatus.portexp)

* writeString_P("==> MAX7311 INT_N!!!");

*

*/

void task_checkINTs(void)

{

if(IO_SENSOR_INT1_PIN & IO_SENSOR_INT1_IN) // XBUS INT1 -> PJ3 (PCINT12)

interrupt_RP6SBstatus.int1 = true;

else

interrupt_RP6SBstatus.int1 = false;

if(IO_SENSOR_INT2_PIN & IO_SENSOR_INT2_IN) // XBUS INT2 -> PJ6 (PCINT15)

interrupt_RP6SBstatus.int2 = true;

else

interrupt_RP6SBstatus.int2 = false;

if(IO_SENSOR_INT3_PIN & IO_SENSOR_INT3_IN) // XBUS INT3 -> PJ5 (PCINT14)

interrupt_RP6SBstatus.int3 = true;

else

interrupt_RP6SBstatus.int3 = false;

// if(IO_SENSOR_INTU_PIN & IO_SENSOR_INTU_IN) // XBUS INTU -> PJ4 (PCINT13)

// interrupt_RP6SBstatus.intu = true;

// else

// interrupt_RP6SBstatus.intu = false;

}

max7311IOs_t inport;

uint8_t readyBusbuff;

uint8_t pressedButton;

/**

* This function checks all I/O ports (I/O 0.0..1.7)

* of the MAX7311 sequentially!

* You must call this function frequently out of

* the main loop.

* The I/O port values (true/false) are read into

* the global inport variable.

* The global variables readyBusbuff (2-Wire Bus

* Buffer: Enable) and pressedButton (Button S1:

* Pressed) contain actual values (true/false)

* after execution of this task.

*

* Examples:

*

* if (inport.rdy_busbuff)

* writeString_P("I/O 0.3: High");

* else writeString_P("I/O 0.3: Low");

* if (!inport.drdy_magacc)

* writeString_P("I/O 1.5: Low");

* if (pressedButton)

* writeString_P("Button pressed!");

*

*/

void task_RP6SensorBoard(void)

{

I2CTWI_transmitByte(I2C_SENSOR_PORTEXP_ADR, MAX7311_INPUT_PORT1);

I2CTWI_readBytes(I2C_SENSOR_PORTEXP_ADR, registerBuf, 2);

inport.word = (registerBuf[1] << 8) + registerBuf[0];

readyBusbuff = inport.rdy_busbuff;

pressedButton = inport.io2_i2c;

pressedButton = !pressedButton;

}

max7311IOs_t outport;

/**

* Updates the I/O ports with current value from

* the global outport variable!

* If one or more port pins were configured as

* output before, they will be set (high) or

* cleared (low).

*

* Example:

*

* outport.word = 0b0000000000001001;

* MAX7311_update();

* // This clears all I/O ports and sets

* // the ports I/O 0.0 and I/O 0.3!

*

* // Other possibility:

* outport.pwr_sharp_f = true;

* MAX7311_update();

* // This sets I/O 0.1 and does not

* // affect any other I/O port!

*

*/

void MAX7311_update(void)

{

I2CTWI_transmit3Bytes(I2C_SENSOR_PORTEXP_ADR, MAX7311_OUTPUT_PORT1, outport.word, (outport.word>>8));

}

/**

* Writes the 16-bit data to a MAX7311.

* The data are output with those I/O ports that

* were configured as output before.

*

* Input: data -> Data word

*

*/

void MAX7311_write(uint16_t data)

{

outport.word = data;

MAX7311_update();

}

/**

* Initializes the I/O Port Expander after power

* on.

*

* Hint: If USE_PD5 is defined in the

* configuration header file, this

* function uses the RP6M256 portpin,

* that is connected to plug I/O: Pin 9

* instead of MAX7311 I/O 1.0!

*

*/

void MAX7311_init(void)

{

#ifdef USE_PD5

MAX7311_write_cfg(MAX7311_CONFIG_USE_PD5);

IO_SENSOR_TCA4311A_EN_DDR |= IO_SENSOR_TCA4311A_EN_IN; // Output

IO_SENSOR_TCA4311A_EN_PORT |= IO_SENSOR_TCA4311A_EN_IN; // High

#else

MAX7311_write_cfg(MAX7311_CONFIG_DEFAULT);

#endif

MAX7311_write(MAX7311_OUTPUT_DEFAULT);

}

/*****************************************************************************/

// I2C Real Time Clock (RTC DS1339):

/**

* This function converts a BCD to a DEC value.

*

*/

uint8_t BCD2DEC(uint8_t bcd)

{

return ((bcd >> 4) * 10 + (bcd & 0x0f));

}

/**

* This function converts a DEC to a BCD value.

*

*/

uint8_t DEC2BCD(uint8_t dec)

{uint8_t units = dec % 10;

if (dec /= 10) {

return (units + (DEC2BCD(dec) << 4));

}

else {

return units;

}

}

/**

* Sends the configuration byte to a DS1339.

*

* Input: Config byte for control register

*

*/

void DS1339_write_cfg(uint8_t config)

{

I2CTWI_transmit2Bytes(I2C_SENSOR_RTC_ADR, DS1339_CONTROL, config);

}

/**

* Initializes the DS1339 Trickle Charger

* function to the default for the RP6 Sensor

* Board: One diode and 2kOhm resistor.

*

*/

void DS1339_init(void)

{

I2CTWI_transmit2Bytes(I2C_SENSOR_RTC_ADR, DS1339_TRICKLE_CHARGER, DS1339_TRICKLE_CHARGER_DEFAULT);

}

/**

* Reads all data registers of the Real Time Clock (RTC).

* They are stored in the time & date variables defined in

* the library header.

*

*/

void DS1339_read(void)

{

I2CTWI_transmitByte(I2C_SENSOR_RTC_ADR, DS1339_SECONDS);

I2CTWI_readBytes(I2C_SENSOR_RTC_ADR, registerBuf, 7);

rtc_time.second = BCD2DEC(registerBuf[0]);

rtc_time.minute = BCD2DEC(registerBuf[1]);

rtc_time.hour = BCD2DEC(registerBuf[2] & 0x3f);

rtc_date.weekday = (registerBuf[3] & 0x07);

rtc_date.day = BCD2DEC(registerBuf[4]);

rtc_date.month = BCD2DEC(registerBuf[5] & 0x7f);

if(registerBuf[5] & 0x80) rtc_date.year = 100;

else rtc_date.year = 0;

rtc_date.year += BCD2DEC(registerBuf[6]);

rtc_date.year += 2000;

rtc_time.dst = 0;

#ifdef CALC_DST

// Calculate MESZ (DST):

uint8_t wday = rtc_date.weekday; // Weekday [1..7 = R_MO..R_SU]

if(wday == 7) wday = 0;

if(rtc_date.month < 3 || rtc_date.month > 10) {

return;

}

if((rtc_date.day - wday >= 25)

&& (wday || rtc_time.hour >= 2)) {

if(rtc_date.month == 10)

return;

}

else {

if(rtc_date.month == 3) {

return;

}

}

rtc_time.dst = 1;

#endif

}

/**

* Writes the time & date infos in the variables defined in

* the library header to the Real Time Clock (RTC).

*

*/

void DS1339_write(void)

{

registerBuf[0] = DS1339_SECONDS;

registerBuf[1] = DEC2BCD(rtc_time.second);

registerBuf[2] = DEC2BCD(rtc_time.minute);

registerBuf[3] = DEC2BCD(rtc_time.hour);

registerBuf[4] = rtc_date.weekday;

registerBuf[5] = DEC2BCD(rtc_date.day);

registerBuf[6] = DEC2BCD(rtc_date.month);

registerBuf[7] = DEC2BCD(rtc_date.year - 2000);

I2CTWI_transmitBytes(I2C_SENSOR_RTC_ADR, ®isterBuf[0], 8);

}

/*****************************************************************************/

// I2C Temperature Sensor (LM75B):

/**

* Sends the configuration byte to a LM75B.

*

* Input: Config byte for Conf register

*

*/

void LM75B_write_cfg(uint8_t config)

{

I2CTWI_transmit2Bytes(I2C_SENSOR_TEMP_ADR, LM75B_CONF, config);

}

uint8_t temperature_low;

uint8_t temperature_high;

/**

* Reads the two data registers of the temperature

* sensor's Temp register.

* They are stored in the variables temperature_low

* and _high.

*

*/

void LM75B_read(void)

{

I2CTWI_transmitByte(I2C_SENSOR_TEMP_ADR, LM75B_TEMP);

I2CTWI_readBytes(I2C_SENSOR_TEMP_ADR, registerBuf, 2);

temperature_high = registerBuf[0];

temperature_low = registerBuf[1];

}

double temperature; // Temperature [°C]

/**

* Calculates and returns the temperature value

* by using the data read from the LM75B with

* the function LM75B_read(). The sensor is

* designed for 11 bit measurement and 0.125°C

* resolution.

*

*/

double LM75B_calculate(void)

{

int16_t tempraw = 0;

double temp;

tempraw = (getTemperatureHigh() << 8) | getTemperatureLow();

tempraw >>= 5;

if (tempraw & 1024) // Calculate temperature

tempraw = (tempraw & 1023) - 1024;

else

tempraw = tempraw & 1023;

temp = tempraw * 0.125;

return temp;

}

/**

* Performs a 11 bit measurement and returns the

* temperature [°C]. The sensor has a measuring

* cycle of 100ms. So it makes no sense calling

* this function at a frequency above 10Hz.

*

*/

double LM75B_measure(void)

{

// LM75B_init();

LM75B_read(); // Read data

return (LM75B_calculate()); // Calculate value

}

/*****************************************************************************/

// I2C Servo Controller (PCA9685):

/**

* Call this once before using the servo function.

*

* Input: PWM frequency [40..1000 Hz]

*

* Hints: - Default servo frequency is 50 Hz!

* - The servo power is NOT switched on by

* this function!

*

* There is also a macro initServo(freq), which

* does exactly the same as this function.

*

* Example:

* initServo(50);

*

*/

void PCA9685_init(uint16_t freq)

{

outport.oen_servo = false; // I/O 1.3: Low

MAX7311_update();

if ((freq < 40) || (freq > 1000)) freq = 50;

I2CTWI_transmitByte(I2C_SENSOR_SERVO_ADR, PCA9685_MODE2);

uint8_t last_mode = I2CTWI_readByte(I2C_SENSOR_SERVO_ADR);

last_mode &= ~PCA9685_MODE2_INVRT; // Clear INVRT bit

last_mode |= PCA9685_MODE2_OUTDRV; // Set OUTDRV bit

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_MODE2, last_mode);

I2CTWI_transmitByte(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1);

last_mode = I2CTWI_readByte(I2C_SENSOR_SERVO_ADR);

last_mode |= PCA9685_MODE1_AI; // Set AI bit

uint8_t mode1 = last_mode;

mode1 |= PCA9685_MODE1_SLEEP; // Set SLEEP bit

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1, mode1);

uint8_t prescale = (uint8_t) (F_PCA9685 / 4096 / freq - 0.5);

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_PRE_SCALE, prescale);

last_mode &= ~PCA9685_MODE1_SLEEP; // Clear SLEEP bit

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1, last_mode);

mSleep(1);

last_mode |= PCA9685_MODE1_RESTART; // Clear RESTART bit

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1, last_mode);

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_LED8_ON_H, 0x10);

return;

}

/**

* Returns the channel belonging to a servo number.

*

* Input: number -> Servo number [1..8]

*

*/

uint8_t servo(uint8_t number)

{

uint8_t channel;

switch (number) {

case 1 :

channel = CH_SERVO_1; break;

case 2 :

channel = CH_SERVO_2; break;

case 3 :

channel = CH_SERVO_3; break;

case 4 :

channel = CH_SERVO_4; break;

case 5 :

channel = CH_SERVO_5; break;

case 6 :

channel = CH_SERVO_6; break;

case 7 :

channel = CH_SERVO_7; break;

case 8 :

channel = CH_SERVO_8; break;

default : channel = CH_SERVO_1;

}

return channel;

}

/**

* This is the servo position set function.

*

* Input: channel -> Channel number [1..16]

* pos -> Servo position [SERVOx_LT..SERVOx_RT]

*

* Hints: - A servo position of 205 means 1 ms servo impulse,

* a position of 410 means a 2 ms servo impulse!

* You may calculate the servo impulse length by:

* ==> Impulse [ms] = servo position / 204.8 <==

* (Formula only valid for a PWM of 50 Hz!)

*

* There is also a macro setServo(servo, pos), which

* does nearly the same as this function, but the first

* parameter is the servo and NOT the channel number.

*

* Example:

* setServo(2,300);

*

*/

void PCA9685_set(uint8_t channel, uint16_t pos)

{

if ((channel == 0) || (channel > 16))

return;

uint8_t reg = channel * 4 + 4; // Register LEDx_OFF_L

I2CTWI_transmit3Bytes(I2C_SENSOR_SERVO_ADR, reg, (pos & 0x00ff), (pos >> 8));

}

/**

* If the servos are not moving for a while, the

* servo function can be stopped with this

* function (PCA9685 set to sleep mode).

*

* Hint: The servo power is NOT switched off by

* this function!

*

*/

void PCA9685_shutdown(void)

{

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_ALL_LED_OFF_H, 0x10);

I2CTWI_transmitByte(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1);

uint8_t mode1 = I2CTWI_readByte(I2C_SENSOR_SERVO_ADR);

mode1 |= PCA9685_MODE1_SLEEP; // Set SLEEP bit

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1, mode1);

}

/**

* If the servo function was stopped with the

* function PCA9685_shutdown() before, it can be

* (re)started again with this function.

*

* Hint: The servo power is NOT switched on by

* this function!

*

*/

void PCA9685_restart(void)

{

I2CTWI_transmitByte(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1);

uint8_t mode1 = I2CTWI_readByte(I2C_SENSOR_SERVO_ADR);

if (mode1 & PCA9685_MODE1_RESTART) { // RESTART bit set?

mode1 &= ~PCA9685_MODE1_SLEEP; // Clear SLEEP bit

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1, mode1);

mSleep(1);

mode1 |= PCA9685_MODE1_RESTART; // Clear RESTART bit

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_MODE1, mode1);

I2CTWI_transmit2Bytes(I2C_SENSOR_SERVO_ADR, PCA9685_ALL_LED_OFF_H, 0);

}

}

/**

* With this function you can switch the servo

* power on or off.

*

* Input: pwr -> 0 (false) = servo power off

* >0 (true) = servo power on

*

* Hints: - If connected servos are not used, you

* should always switch the servo power off

* (default) to save energy!

* - The PCA9685 is NOT restarted or put into

* shutdown mode by this function!

*

*/

void setServoPower(uint8_t pwr)

{

if(pwr > 0)

outport.pwr_servo = true; // I/O 1.4: High

else

outport.pwr_servo = false; // I/O 1.4: Low

MAX7311_update();

}

/*****************************************************************************/

// I2C LED Driver (TCA6507):

/**

* Sends the configuration byte to TCA6507's

* internal registers.

*

* Input: reg -> Register address [0..10]

* config -> Config byte for internal

* registers

*

* Hints: - With this function you can write to

* all internal registers of the LED

* driver, see "Registers:" in the

* library header file!

* - Mainly you will use this function

* for setting time (regs 3..7) and

* intensity (regs 8, 9) values.

*

* Example:

* TCA6507_write_cfg(TCA6507_MAXIMUM_INTENSITY,0x77);

*

*/

void TCA6507_write_cfg(uint8_t reg, uint8_t config)

{

if(reg > 10) reg = 0;

I2CTWI_transmit2Bytes(I2C_SENSOR_LEDDRIVER_ADR, reg, config);

}

uint8_t select[3];

/**

* Updates the LED driver select registers (0..2)

* with the global select array!

*

* Hint: - Also have a look at Table 4 in the

* TCA6507 datasheet!

*

*/

void TCA6507_update(void)

{

I2CTWI_transmit4Bytes(I2C_SENSOR_LEDDRIVER_ADR, (TCA6507_SELECT0 | 0x10), select[0], select[1], select[2]);

}

/**

* This is the LED state set function.

*

* Input: led -> LED number [0..6]

* state -> LED state [0..7]

*

* Hints: - Possible driver states [0..7] see

* "Output states:" in the library

* header file!

* - Also have a look at Table 4 in the

* TCA6507 datasheet!

*

* There is also a macro setLED(led, state), which

* does exactly the same as this function.

*

* Example:

* setLED(1,4);

* // Switches LED1 ON

* // ... OR ...

* setLED(LED1,STATE_ON);

* // does the same.

*

*/

void TCA6507_set(uint8_t led, uint8_t state)

{

uint8_t i, mask;

if(led > 6) led = 0;

led = 1 << led;

mask = 1;

for(i = 0; i < 3; i++) {

select[i] &= ~led;

if(state & mask)

select[i] |= led;

mask <<= 1;

}

TCA6507_update();

}

/**

* If the LEDs are not needed for a while, the

* LED driver can be stopped with this function

* (TCA6507 set to shutdown mode).

*

*/

void TCA6507_shutdown(void)

{

outport.en_leddriv = false; // I/O 0.4: Low

MAX7311_update();

}

/**

* If the LED driver was stopped with the

* function TCA6507_shutdown() before, it can be

* (re)started again with this function.

*

*/

void TCA6507_restart(void)

{

outport.en_leddriv = true; // I/O 0.4: High

MAX7311_update();

}

/**

* Initializes the LED driver after power on by

* switching all LEDs off.

*

*/

void TCA6507_init(void)

{

select[0] = 0;

select[1] = 0;

select[2] = 0;

TCA6507_update();

}

/*****************************************************************************/

// I2C 3D Magnetometer & Accelerometer (LSM303DLHC):

// --------------------------------------------

// LSM303DLHC accelerometer functions: